What is an Escalator Chain?

The steps of an escalator are connected in series and travel along a track system. This helps the steps move in the correct direction, and also guides them to rotate at transition sections so that they create a cycle.

The escalator chain is a steel chain that moves the steps on an escalator. The chain has a tensile strength of between 6 and 30 tons.

The Steps

Escalators use chains of individual steps on a pair of tracks to move people from one floor of a building or structure to another. They are commonly found in department stores, shopping malls and airports worldwide.

The step chains are typically about every 400 mm. They have a tensile strength of between 6 and 30 tons. The chain pitch should be as small as possible to minimize chordal action.

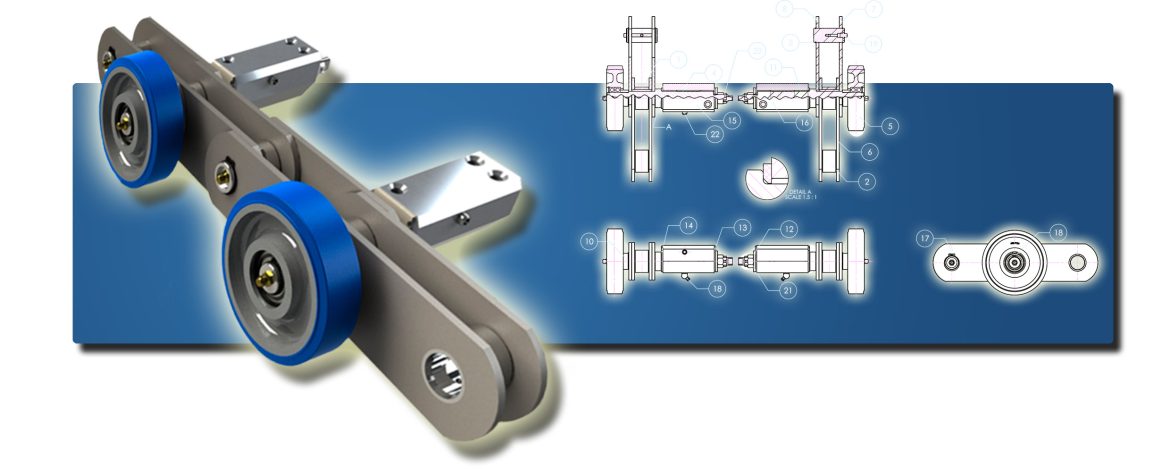

To operate, the escalator step chains are pulled from bottom to top and back to the bottom. Each chain consists of a series of links that are connected to each other by axles, rollers and side plates. The side plates of the next link in line are attached to each axle on both sides of the roller, thereby holding the roller and axle together (see FIGS.2).

Each link is then linked to a chain wheel via a pivot point. The angular pitch of the chain wheels is determined by the equidistant distance between the tooth spaces in the links. The pitch is usually about 45 deg.

In order to maintain their lateral position on the escalator or moving walkway, the step chain rollers are fitted with a track side wall that engages the sides of the rollers. This enables the rollers to be angled and curved, which provides improved step chain guidance and longer roll tread life.

Alternatively, the step chain rollers may be fixed with elastomeric track-engaging treads mounted in a recess on the side of the roller circumference. This reduces friction between the roller and the underlying surface of the escalator or moving sidewalk, which also contributes to longer roller tread life.

A comb bearer, which sits between the stationary escalator chain floor plate and the moving step, is often used in conjunction with the aforementioned cleats to create a “comb effect”. The comb effect minimizes gaps between the stair and landing, while also reducing slippage hazards.

Escalators also use a balustrade, which is usually made of either metal or glass and supports the handrails. The balustrade also serves as a safety barrier, preventing passengers from falling into the rail.

The Chains

The chains that make up an escalator chain are looped around two pairs of gears and rotated by an electric motor. Instead of moving a flat surface like in a conveyer belt, these loops move a series of interlocking steps, which then enter into a special guide system at the top and bottom of a larger metal structure called a truss to create a level platform for passengers to board or exit.

Most escalators have solid steps made of one piece die -cast steel or aluminum. These are cleated with comb-like protrusions that mesh together with the bottom and top platform comb plates and the following steps in the chain. The combs are designed to hold the riser and tread of the steps as they pass each other, ensuring that all the steps will be aligned as they travel along the chain.

Escalators are often used in commercial buildings, such as department stores and airports. They are popular because they transport people from one floor to another, much more effectively than elevators.

A typical escalator is powered by an electric motor that rotates the chain loops and also causes handrails to move. This makes it easier for passengers to hold onto the rails for stability and safety as they ride the escalator.

In addition, the chain loops on an escalator are connected to two sets of tracks that each have its own set of wheels. The upper set of wheels is connected to the rotating chains and pulls on a drive gear at the top of the escalator, while the lower set of wheels simply glides along its track, following behind the first set.

The spacing of these tracks ensures that the steps stay level as they travel down and up the escalator, making it easy for passengers to navigate them. As the steps are moved up and down, they collapse on each other to form a flat platform that’s easier to walk on.

To reduce entry noise, some escalators have guides that cause the chains to run tangentially onto the chain wheels, as opposed to running on them. However, this approach is not ideal because it has several drawbacks: Firstly, the forces on the wheel are too great; secondly, the chain wheels would be too loaded; and thirdly, a large oscillating movement of the redirecting station could occur.

The Gears

Escalators are power-driven, continuous moving stairways that are used in many places around the world, such as airports and public buildings. They are designed to carry large numbers of people in a short amount of time.

Most escalators have single-piece aluminum or stainless steel steps that move on a system of tracks in a continuous loop. They are driven by a motor and chain system inside a truss, a metal structure that extends between the bottom and upper landing platforms.

The motor drives a gearbox that converts the rotational motion of the motor into an up-and-down motion that propels the escalator. In turn, this gearbox drives a series of wheels that move the handrail on the escalator.

In addition to the escalator chain motor, the escalator has a pair of chains that are looped around two pairs of gears. The gears are turned by an electric motor, which in turn rotates the chain loops.

A set of wheels connected to the rotating chains moves along a track on each step, and another set of wheels glides along a separate track behind it. This spacing allows the steps to level off at the top and bottom of the escalator, making them flat enough for passengers to walk on.

Each step has a yellow demarcation line that shows its edges. It is cleated with comb-like protrusions that mesh with the bottom and top platform comb plates.

These plates are made from a combination of steel and stainless steel based on the escalator’s use and customer preference, and can be in different shapes and sizes. They are a critical part of the safety system that protects passengers from getting caught in the moving escalator stairs.

There are also safeguards for the handrail on both sides of the escalator, including a barrier made from glass or stainless steel that protects against collisions. This is a great way to ensure safety for passengers, especially women wearing saris or clothing made of soft materials.

An escalator chain is a crucial component of the escalator’s functionality, so it should be of high quality. It should be able to withstand heavy loads while keeping maintenance costs low. In addition, the escalator chain should be free from any grease or oil. This eliminates any unnecessary lubricating agents, which reduces maintenance and life cycle costs.

The Motor

Escalators use an electric motor to power the chain loops that drive the steps. The motor and chain system are housed inside what is called a truss, a metal structure that extends between the lower and upper floors of an escalator.

The motor in an escalator rotates the main chain loops and also causes the handrails to move. The handrails are a rubber conveyor belt that is looped around a series of wheels and designed to move at the same speed as the steps, which gives riders stability.

In addition to the chain, an escalator uses gears to control the speed at which the steps travel. The gears are driven by the motor and can vary from a minimum of 90 feet per second to a maximum of 180 feet per second.

Some escalators also include a brake mechanism. This mechanism is activated by the chain when a safety switch is pressed, which can cause the escalator to stop abruptly. If the brake is not set correctly, passengers could lose their balance and fall down the escalator.

Another method to reduce pulsation is to change the shape of the chain rail with protrusions or depressions at certain points just before the teeth on the sprockets, which changes the speed of the steps. This can suppress pulsation in the horizontal section of the chain, which is uncomfortable for passengers.

An escalator also has a chain guide, which can influence the entry angle of the chains on the first and second chain wheels, wherein the guide is arranged in such a way that the first and/or the second chain wheel’s effective lever arm is offset from a maximum by no more than +-20% when the escalator is at a minimum effective lever arm (chain on chain). This reduces entry noise (chain on chain) and reduces the oscillating movement of the redirecting station, which has a positive effect on running smoothness.

The step chain on an escalator is made of a steel wire that is formed into a chain and attached to each step with links. The tensile strength of this chain ranges from 6 to 30 tons.