How to Choose a UV Panel for Interior Design

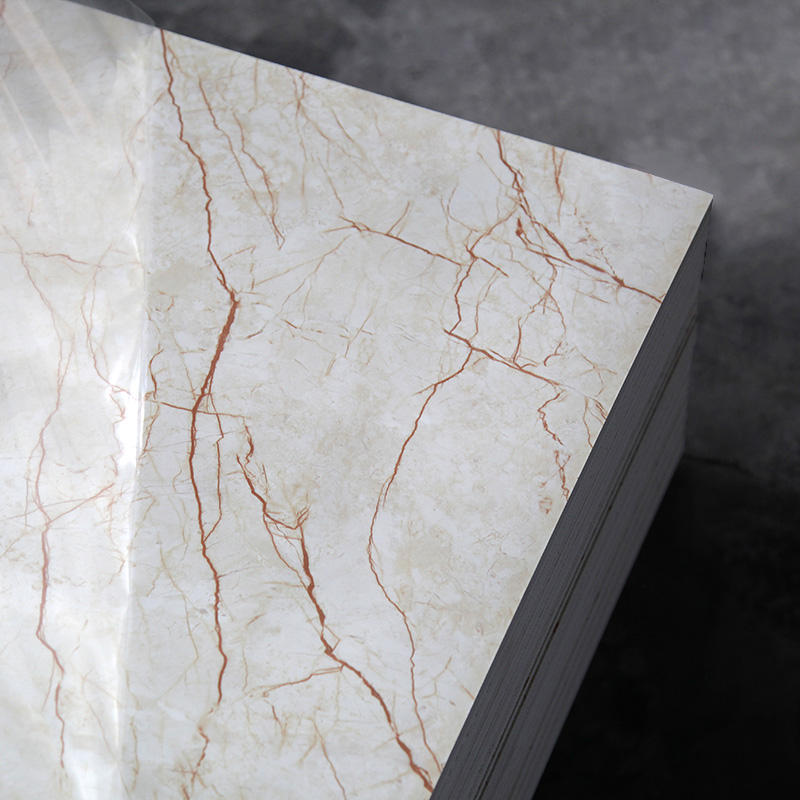

UV panel is a highly durable and versatile product. Its high durability and resistance to moisture makes it the ideal choice for a wide variety of interior design applications.

It can be used for kitchen shutters, wall paneling embellishments and various furniture products. The lustrous finish it offers makes it perfect for any interior decor.

Benefits

UV panels, also known as ultraviolet disinfection devices, are used in many commercial settings to control microorganisms in sewage or other wastewater. When used correctly, UV devices can help ensure the disinfection process is done without the use of chemicals and other waste products.

There are several benefits to using a UV panel, including the ability to control microorganisms in the environment and improve air quality. These benefits can be useful for people with asthma or other respiratory conditions, those who suffer from allergies, and anyone who wants to prevent illness.

In addition, UV disinfecting devices can be used to protect your heating and cooling system from harmful microorganisms. They can reduce clogged filters, increase energy efficiency and extend the life of your equipment.

As a result, UV disinfecting devices are considered a valuable investment in the health of your home and family. They can improve the quality of the indoor air you breathe, preventing health problems like rashes, eye irritations, fatigue, headaches and more.

Unlike traditional chemical pesticides, UV pesticidal devices are not subject to pre-market approval by the Environmental Protection Agency (EPA). However, EPA does require manufacturers to report data supporting the efficacy of their devices.

The most common method of determining the effectiveness of UV devices is through laboratory tests, which can be conducted by a reputable lab that specializes in antimicrobial testing. These studies can measure the device’s ability to kill various pathogens under tightly controlled laboratory conditions.

Another common method of determining the effectiveness of UV disinfecting devices is through dose-response models. These studies involve measuring the amount of UV-C radiation that a device delivers to its target area and then using those numbers to estimate its efficacy.

In addition to helping determine the effectiveness of a UV disinfecting device, dose-response models can also help you make an informed purchase decision by identifying potential problems. For example, if the device delivers a large amount of UV-C light but fails to kill bacteria, this could indicate that the device has not been properly optimized or that the manufacturer has not done enough research to understand how to make the device more effective.

Cost

The cost of using a UV panel depends on several factors, including the type of system you use, the intensity you need, and how long it UV panel will last. You can also lower the overall cost by buying a more efficient model that uses fewer lamps and less energy than standard fluorescent fixtures.

Whether you need to disinfect wastewater or improve ID card security, a UV panel will help you keep your facility clean and healthy. This will not only protect employees from disease-causing microorganisms, but it can also save you money on chemicals and associated byproducts.

A UV panel costs approximately $1,500 to $2,500 per room with a ceiling height of eight to 13 feet. The price includes a system that contains one or more ultraviolet germicidal lamp fixtures, a control unit that manages the lamps and monitors their status, and a power supply.

If you want to minimize your investment, consider installing multiple UV fixture systems in different rooms. This will ensure that each area receives the desired level of disinfection and minimize the number of fixtures you need to buy in the future.

Another way to reduce the cost of your UV system is to replace its lamps with LED models that have a 2-year replacement schedule. These fixtures are more efficient, and they also have a longer life span than their standard counterparts.

For even more efficiency, you may want to consider adding UV LED strip lights to your existing fixtures. These are made of many UV LEDs that are mounted on a flexible circuitboard around half an inch in width.

These panels can be installed on walls, floors, or even ceilings, and they are available in various colors to complement your building’s interior design. They have a UV panel high output of energy and can be used to create energy even on cloudy days.

While traditional solar panels can absorb visible light and convert it into electricity, they can’t absorb the much higher energy of ultraviolet (UV) light. This is because UV light has a much longer wavelength than visible light, and it contains more energy per photon. However, a young man from the Philippines has developed a resin solar panel that can transform UV light into renewable energy.

Durability

Durability is one of the most important factors in choosing a UV panel. Architects want to select a material that will not only be aesthetically pleasing, but will also stand up to the wear and tear that comes with daily traffic and natural elements such as rain and hail.

The amount of durability a solar panel can achieve will depend on where it is installed and how it is treated. In areas where sandstorms are common, for example, it is worth opting for a solar panel that has been tested to withstand harsh conditions.

Extreme weather events such as heat waves and hurricanes can cause dramatic temperature changes which can affect the overall lifespan of a panel. This can lead to mechanical damage, cracks, or bending of the component parts.

Another factor affecting a solar panel’s durability is the sunlight it’s exposed to. UV rays from the sun can degrade crystalline silicon cells in a panel over time, reducing its power output.

The same rays can also attack the epoxy that is used to bind carbon fiber products. When exposed to prolonged amounts of UV light, the epoxy can break down, causing the carbon fiber to fade and become brittle.

This degradation is called ultraviolet light-induced degradation (UVID). It can last days or even weeks and will reduce the panel’s performance.

It is not only a challenge for the production of synthetic materials, but it is also an issue with many carbon fiber products, especially those that have been coated with UV-stable epoxy resin.

To combat the effects of the elements on solar panels, manufacturers have developed new technologies and methods for reducing the rate of degradation. These include a low-temperature initial setup, and a coating that can be applied after setup to prevent further damage from the environment.

Aside from enhancing durability, these new processes can also reduce the cost of the panels by decreasing manufacturing costs and increasing efficiency. As a result, they can be used in a variety of applications that require a durable product.

It is crucial to choose a durable phenolic wall panel that can withstand high levels of UV exposure and traffic. This will ensure that you get the most out of your investment and preserve the integrity of your design.

Versatility

UV panels can be found in a variety of applications. The most obvious is in the food and beverage industry where UV systems can break down trace chemicals like ozone, chlorine and total organic carbon, while also inactivating harmful bacteria and viruses. This allows for higher throughput and more accurate testing. This also makes for a safer work environment for staff and a less likely accident prone facility. For commercial properties looking to add a wow factor to their space, UV panels are a logical choice. They are also an excellent choice for educational and entertainment facilities looking to provide students with a plethora of stimulating hands-on activities. The most important thing is to choose a manufacturer with the resources to deliver your unique needs on time and on budget.