What Is a Fiber Array?

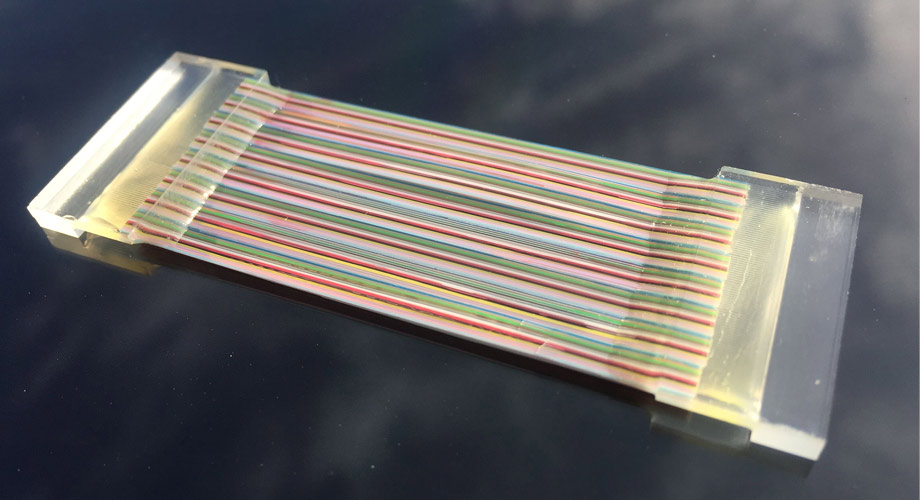

A fiber array is a package of SM, MM or PM optical fibers clad in a suitable material to prevent light leakage. It is mainly used for encapsulation of opto-electrical integrated circuits, optical planar structures (PLC power splitter) or sensors.

The process of producing an optical fiber array is complex and requires precision on a submicron level in order to reduce connection loss. Moreover, it is difficult to produce arrays with low fiber count in smaller diameters.

High-precision V-groove substrate processing

Optical fiber arrays are used in optical switching and sensing applications where spatial optical data is needed. They are often made of glass or silicon substrates and are fabricated with high-precision machining techniques or etching processes. However, these methods are not suitable for mass production, and therefore, it is difficult to reduce the manufacturing cost of an optical fiber array.

According to one embodiment of the present invention, an optical fiber block is provided that includes an optical-fiber-alignment portion and a stress-reduction-depth portion, which are formed on a silicon wafer by wet-etching operations. The optical-fiber-alignment portion accommodates the bare optical fibers of a ribbon fiber, while the stress-reduction-depth portion is etched to a predetermined depth for reducing stresses.

The optical-fiber-alignment portion includes an array of V grooves arranged to accommodate the bare optical fibers of the ribbon fiber. In the array, first V grooves at both sides of the ribbon fiber are larger than the second V grooves disposed in the middle of the ribbon fiber. The array of V grooves is formed on the silicon wafer by primary wet-etching operations and secondary wet-etching operations.

In addition to the array of V grooves, a ferrule is provided that includes alignment guide holes whose positions are defined by the first and second V grooves on the surface of the silicon wafer. The optical fibers are inserted into the alignment guide holes on the ferrule, and the ferrule is fixed with an adhesive injected through an adhesive filling hole.

A polymer thermoplastic material (thermoplastic resin) is used for the ferrule. The polymer thermoplastic material exhibits a small deformation amount at the time of thermal shrinking or after molding, which is suitable for forming the ferrule with high dimensional precision.

Another embodiment of the present invention provides an optical fiber coupler consisting of an out-of-plane refractive microlens array and two fiberport collimators, which are fabricated using 3-D UV-lithography of SU-8 photoresist. The optical axis of each pixel of the microlens array is parallel to the substrate, and each pixel of the fiberport collimator is pre-aligned with the corresponding pixels of the microlens array in lithography mask design.

Fiber etching technology

Fiber arrays are used to increase the optical data transmission rate of sensors and photonic circuitry. Several methods are available to create them, including laser marking and etching. Both methods work by releasing pulses of energy at specific intervals. However, different lasers can affect the outcome of each process. For instance, a fiber laser generates more energy per pulse than a CO2 laser. This is why it is preferred for marking metals.

Another option for creating a fiber array is to use a reactive ion etch (RIE). This method uses a plasma etch to remove material on the wafer substrate. This can be useful before a mechanical dicing blade is used for die singulation.

This RIE etching process can be performed on any material, including glass. This technique allows a large number of fibers fiber array to be etched at once. This is especially beneficial when a tapered point on the fiber is needed for coupling to a laser.

Alternatively, this technology can be used to fabricate fiber probes for high-density near-field optical storage. It can also be used to fabricate hemispherical microlens arrays for sensor applications.

The hemispherical arrays are patterned on the device in a grid, with each cell corresponding to one microlens. This pattern can then be transferred down to the layer below through an anisotropic plasma etch.

A RIE etching technique is also employed to anneal the etched surface of the silicon v-groove. This can be very effective at creating smooth sidewalls that do not compromise the structural integrity of the wafer substrate.

Besides being more precise than laser marking, etching and engraving processes are also more cost-effective. They can produce a much wider range of colors than laser annealing.

In addition, etching can be performed with lower power lasers than engraving. This can reduce costs for larger parts and improve productivity.

A dry etch process is an important aspect of any photonics manufacturing flow. It allows a variety of features to be created on the substrate, such as holes and v-grooves. The etched features can also be manipulated during the fabrication process to create optical features with better optical properties.

Optical fiber manufacturing

Fiber arrays are fabricated by iteratively fusing a bundle of individual optical fibers into a single substrate. The individual fibers maintain their relative positions throughout the length of the bundle. The resulting substrate, which is known as a fiber-tapered array, can be used to manufacture a variety of different components and applications, including photonic circuits and waveguides.

Optical fibers are manufactured in several ways, including by modified chemical vapor deposition (MCVD), outside vapor deposition (OVD), and vapor axial deposition (VAD). Modified chemical vapor deposition allows the production of moderate-to-low loss waveguides. VAD enables the fabrication of highly accurate and highly efficient optical fibers with low losses in the order of tens of micrometers/second.

Most glass optical fibers have a central core and a cladding made of a different material than the core. The cladding usually has a higher refractive index than the core. The cladding also prevents light from leaking out of the core. The cladding can be made of silica, fluorozirconate, fluoroaluminate, and chalcogenide glasses as well as crystalline materials such as sapphire.

When a light ray strikes the cladding, it must strike the surface with an angle greater than the critical angle in order to penetrate through it without leaking out. This critical angle is often reported as the numerical aperture (NA). The NA increases the ability to efficiently couple light into the fiber, but it also increases the amount of dispersion and scattering. The NA of a glass optical fiber is typically about 1.5, but it can be as high as 3 for certain crystalline materials.

The NA of a fiber is often determined by the refractive index of the core and cladding. If the refractive index of the cladding is less than that of the core, the resulting fiber is called a dichroic fiber. This type of fiber is not as useful as a straight-line fiber.

Another type of fiber is a photonic crystal fiber. The refractive index of a photonic crystal fiber is determined by the shape of the periodic structure, rather than by total internal reflection. This type of fiber is not as flexible as a standard glass optical fiber, but it can be designed to carry higher power and be used in many specialized applications.

Optical fiber assembly

Optical fiber arrays have become very popular for use in applications such as DNA analysis. These arrays can be constructed to contain a variety of different materials including beads, cells and single molecules. By combining these components together and using dyes to encode the information, the arrays can be used in standard fluorescence microscopes.

In the production of optical fiber arrays, there are a number of machining processes that must be performed to achieve accuracy and reliability. These processes include cleaving, softening and polishing of the end faces. They also must be performed in an environment that is stable and able to guarantee the precision of the process.

These cleaving and softening processes require high-precision, ultra-precision machining technologies and equipment, as well as fiber array experience and knowledge. In addition, a good inspection system is required to ensure that the processed product meets its specifications.

Another important aspect of the production of optical fiber arrays is a precise positioning of the fiber ends. This must be done carefully, especially in cases where a polarization-maintaining (PM) fiber is being used.

One way of achieving this goal is by employing a spacing fixture that keeps the distance between the individual fiber ends uniform. Several technological ideas have been proposed that utilize the shape of the fibers and the cladding diameter to maintain the relative separation between the ends.

A second way of achieving this goal is by providing grooves that allow the insertion of fibers in a straight line. This is accomplished by forming V-grooves that are formed at a predetermined level corresponding to the cladding diameter of the optical fibers.

Similarly, the pitch of the grooves can be narrowed in increments until the fiber ends are properly aligned. This can be done by applying a lubricant or a solvent to the guide substrate and the fibers.

In addition, a covering of the fibers can be positioned at the insertion depth of the grooves. This cover is designed to keep the insertion depth of the fibers at the same level as the cladding diameter of the fibers, while allowing the cladding diameter of the fibers to be increased or decreased by a predetermined amount.