Watertight Cable Joining Device: Enhancing Electrical Connections

Manufacturing

The production of watertight cable joining devices involves a complex process that ensures du

rability and reliability. These devices are designed to provide weatherproof electrical connections, allowing for safe usage in outdoor or moist environments. The manufacturing process begins with the se Moisture-sealed cable splice connector lection of high-quality materials that possess excellent resistance to water and moisture damage. Special attention is given to the design of the connectors, ensuring easy installation and secure wire splicing.

Characteristics

A key characteristic of these devices is their ability to offer a moisture-sealed cable splice connection. This preven wire splice connector waterproof ts any liquid ingress, safeguarding both the cables and electrical components. The connectors are constructed with durable materials such as heat-resistant plastics, rubber seals, and corrosion-resistant metals. This combination guarantees long-term performance under harsh conditions.

Advantages

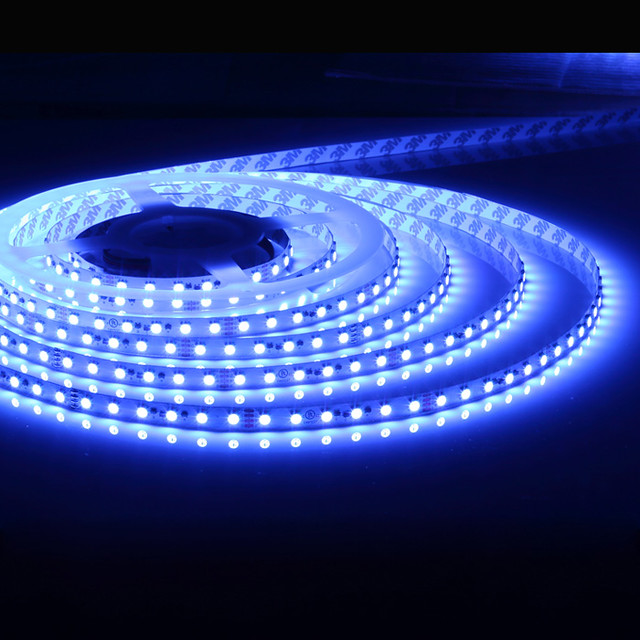

Using a watertight connector offers several advantages in various applications where reliable electrical connections Weatherproof electrical connection terminal are vital. Firstly, it provides protection against water exposure which can cause short circuits or even hazards like electric shocks in some cases. Additionally, these connectors maintain stable electrical conductivity by preventing oxidation or corrosion resulting from moisture intrusion over time.

Usage Method

To ensure proper utilization of waterproof y connector electrical wire splice connectors, it is important to follow appropriate techniques during installation. Begin by preparing clean surfaces o waterproof splice connectors n the wires being connected before carefully stripping off insulation layers using specified tools suited for the job at hand. Once exposed, securely insert each wire into its corresponding terminal within the connector housing while observing correct polarity markings if applicable. Lastly, firmly close the connector’s lid until fully sealed against any potential water entry points.

Selecting an Appropriate Product

When selecting waterproof splice conn wire splice connector waterproof ectors best suited for specific needs, there are few factors worth considering:

1) Environment: Assess whether outdoor exposure or moisture-prone surroundings necessitate greater sealing capabilities.

2) Wire Compatibility: Confirm compatibility between connector size/makeup specifications and wire gauges/diameters being used.

3) Expected Load: E waterproof connector manufacturer valuate the electrical load capacity requirements to ensure chosen connectors can safely accommodate it.

Conclusion

Watertight cable joining devices play an essential role in safeguarding electrical connections from moisture-related damages. By pri wire splice connector waterproof oritizing manufacturing excellence, these connectors offer a reliable and efficient solution for various industries, including telecommunications, outdoor lighting systems, marine applications, and many more. With their easy insta Watertight cable joining device llation process and ability to withstand harsh conditions, these connectors effectively deliver lasting performance while ensuring safety in modern electrical installations. Choose watertight splice connectors today for improved connectivity and peace of mind.