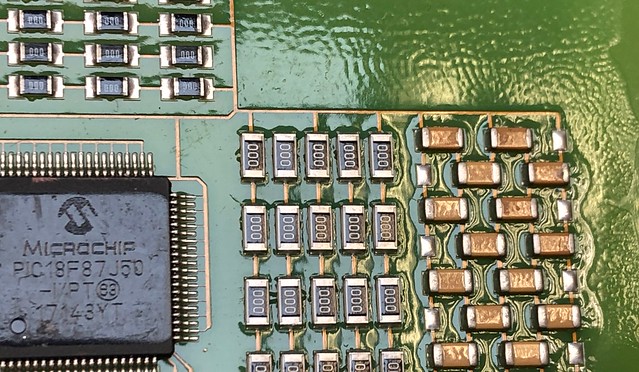

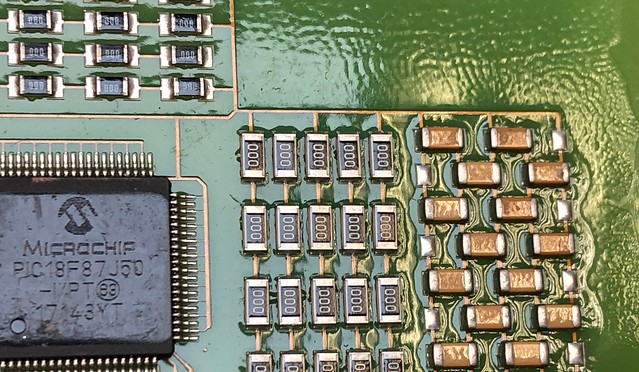

PCBA coating, also known as printed circuit board assembly coatin Ceramic PCB g, plays a crucial role in ensuring the functionality and longevity of electronic devices. This protective l PCBA Coating ayer is applied to PCBs during the manufacturing process to shield them from environmental factors such as moisture, dust, and heat Component-level encapsulation .

Solder mask application is an essential step in the PCBA coating process. This layer protects the PCB from corrosion and helps prevent short circuits caused by solder bridging. Component-l PCB assembly coating evel encapsulation further enhances the durability of electronic components by providing additional protection against physical damage.

One significant advantage of PCBA coating is its ability to improve the reliability and performance of electronic devices. By preventing c PCBA Coating orrosion and other forms of damage, this coating extends the lifespan of PCBs, reducing maintenance costs for manufacturers and end-users alike. Solder mask application

To apply PCBA coating effectively, manufacturers must follow specific guidelines based on the type of substrate material used. Different ma

terials such as aluminum PCBs or ceramic PCBs require different types of coatings to ensure optimal results.

When selecting a supplier for PCBA coating services, it is essential to choose one with a proven track record in quality assurance and customer satis PCBA Coating faction. Look for a supplier that offers customization options tailored to your specific needs and requirements.

In conclusi

on, PCBA coatings are indispensable for enhancing the reliability and performance of electronic devices. By protecting PCBs from environmental factors and physical damage, these coatings contribute significantly to prod Smart door lock supplier uct longevity and user satisfaction.

Overall, investing in high-quality PCBA coatings can help manufacturers maintain their competitive edge in today’s fast-paced electr Aluminum PCB onics market.