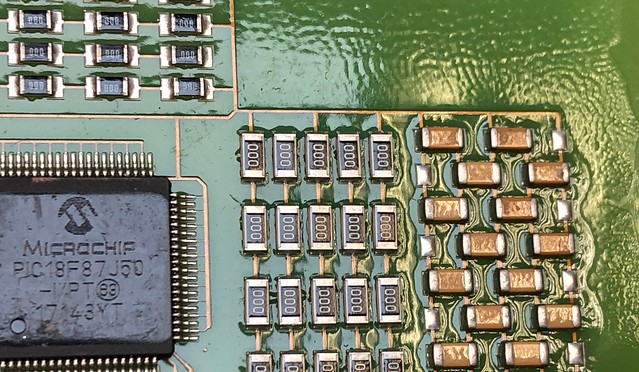

PCBA coating, also known as protective conformal coati PCBA Coating ng, is a crucial step in the PCB assembly process. It provides a layer of protection to the printed circuit board against

environmental factors such as moisture, dust, and temperature fluctuations. Solder mask application is an essential part of this process as it ensure Aluminum PCB s that only specific areas on the board are coated with the protective material.

The use of PCBA coating offers several advantages. Firstly, it prolongs the lifespan of electron Solder mask application ic components by preventing corrosion and short circuits. Secondly, it improves the reliability and performance of the PCB assembly by reducing signal interference and thermal stress. C PCB assembly coating omponent-level encapsulation further enhances Ceramic PCB these benefits by offering additional protection to sensitive parts.

When selecting a PCBA coating for your project, consider factors such as compatib

ility with other materials used in manufacturing, ease of application, and cost-effectiveness. Smart door lock suppliers often rely on specialized coatings tailored to their specific requirements. Aluminum PCBs are p PCBA Coating opular choices due to their lightweight yet durable nature, while ceramic PCBs offer s Smart door lock supplier uperior heat dissipation for high-power applications.

In conclusion, PCBA coating plays a vital role in ensuring the quality and longevity of electronic devices. By understanding its manufacturing process, characteristics, advantages, app Component-level encapsulation lication methods, and selection criteria based on your specific needs , you can make an informed PCBA Coating decision when choosing this essential component for your next project.