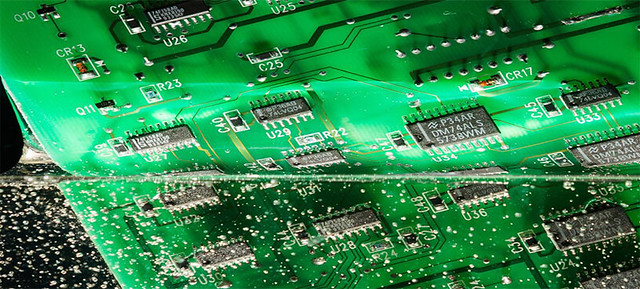

Electronic circu PCBA coating it board coating plays a crucial role in the manufacturing process of PCB assembly. One of the key processes invo PCB manufacturer lved in this is PCBA coating, which provides protection to the electronic components on the board. PCBA coating is also known as board level conformal coating a PCBA Coating nd component-level encapsulation.

PCBA coating involves applying a thin layer of protective material over the asse Electronic circuit board coating mbled electronic circuit boards. This protective material can be acrylic, silicone, epoxy, or urethane-based, depending on the specific requirements of the application. The purpose of PCBA coating is to provide insulatio

n against moisture, dust, chemicals, and temperature variations that could potentially damage sensitive electronic components PCBA Coating .

One of the main advantages of using PCBA coating is its ability t

o extend the lifespan and reliability of electronic devices by preventing corrosion and short circuits. It also helps improve overall performance by reducing signal interference and protecting against environmental factors.

The application m LED PCB ethod for PCBA coatings can vary depending on the type of material being used. Some common methods include spraying, brushing, Ceramic PCB dipping, or selective robotic dispensing. It is essential to ensure

proper coverage and thickness during application to guarantee effective protection.

When selecting a PCBA coating for your PCB manufacturing needs, it’s crucial to consider factors such as compat Board level conformal coating ibility with other materials used in assembly processes, desired level of protection required based on environmental c PCBA Coating onditions or operating parameters, and regulatory compliance standards.