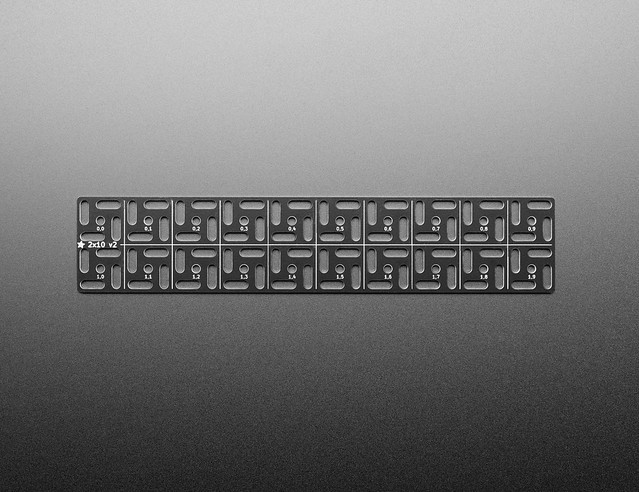

Aluminum PCB

Metal core PCB, Al-PWB (Aluminum Printed Wiring Board), A-PCB (Aluminum PCB), Aluminum clad PCB, I Aluminum PCB manufacturer MS (Insulated Metal Substrate) PCB

Aluminum PCB, Aluminum PCB, Aluminum PCB private label, Aluminum PCB manufacturer, Flexible PCB manufacturer

Introduction:

The world of printed circuit boards has seen significant advancements over the years. One such breakthrough is the aluminum printed cir Metal core PCB cuit board or Aluminum PCB. This article aims to provide an in-depth understanding of how these boards are manufactured and their unique features and advantages over traditional alternatives.

Manufacturing Process:

Aluminum printed circuit boards are typically fabricated using a specialized manufacturing process involving the deposition of a thin layer of aluminum on the base material substrate. The base material can vary based on application requirements Aluminum PCB but commonly includes materials like FR4 epoxy resin or polyimide.

Key Characteristics:

One notable feature of aluminum-based substrates is their excellent heat dissipation capabilities compared to conventional FR4 boards. This c Aluminum PCB haracteristic makes them ideal for applications where efficient heat transfer is crucial.

Additionally, due to their high thermal conductivity properties and low expansion coefficient similar to silicon devices used in electronics packaging industry,aluminium alloys with good A-PCB (Aluminum PCB) electrical insulation properties have become more popular than other metals recently.

Advantages:

There are several advantages associated with utilizing aluminum printed circuit boards. Firstly,their exceptional thermal performance translates into improved reliability and longevity for electronic components that generate significant amounts of heat during operation.

Secondly,the reduced size achieved by eliminating bulky heatsinks allows for space-efficient designs particularly beneficial in applications with size constraints.Lastly,assembling components directly

onto an aluminium substrate simplifies production processes thus improving overall efficiency.

Applications:

Due to its outstanding thermal management characteristics,

Aluminum P turn outingsocks h bingo ncuit Boards find widespread applications across various industries. These include power supplies automotive LED lighting telecommunications equipment and many m Al-PWB (Aluminum Printed Wiring Board) ore.The unique combination of efficient heat dissipation, electrical insulation properties, and reduced size make them suitable for high-power LED applications where proper thermal management is crucial.

How to Select the Right Aluminum PCB:

Selecting the appropriate aluminum printed circuit board involves considering various fa Aluminum PCB ctors. The most critical factor includes determining specific application requirements such as operating temperature range,electrical performance design requirements,size limitations compatibility with existing manufacturing processes or available components amongst others.

In addition, it’s essential to ensure that the chosen aluminum PCB manufacturer has a proven track record in delivering reliable products Aluminum PCB private label meeting industry standards.

Conclusion:

Aluminum PCB lives up to its reputation as an innovative technology for modern electronics applications. Its superior thermal performance coupled with other advantageous properties significantly contributes to enhancing device reliability and over

all system efficiency. Selecting a competent manufacturer plays a vital role in obtaining top-quality aluminum printed circuit boards tailored to individual needs.

By understanding the manufacturing process, key characteristics, advantages, application domains,time effiency,and selection criteria associated with Aluminum PCBs individuals can now make informed decisions wh Flexible PCB manufacturer ile integrating this technology into their projects ensuring optimal outcomes