Silicone O Rings: The Perfect Solution for Various Applications

Introduction:

Silicone o rings are versatile sealing elements used in a wide range of industries and applications. Their superior performance and durability mak Silicone Kitchen Products e them an ideal choice for ensuring tight seals and preventing leaks. In this article, we will explore the manufacturing process, characteristics, adva Liquid silicone gaskets ntages, usage methods, tips for selecting silicone o rings, and conclude with their significance.

Manufacturing Process:

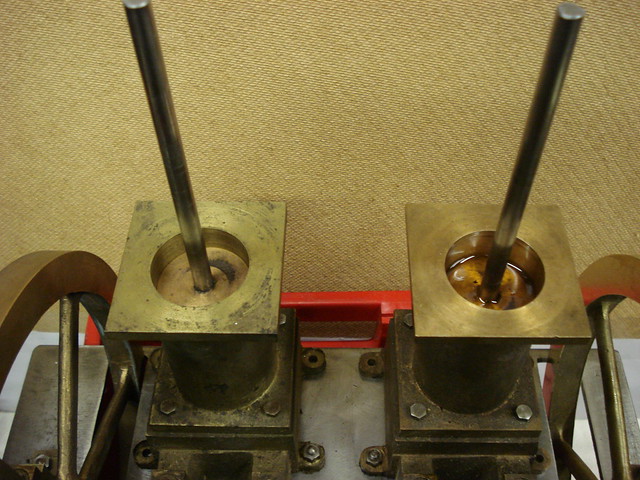

Silicone o rings are typically made from rubberized silicone or molded silicone compounds. Rubberized silicone rings involve blending high-quality silicone polymers with specific filler materials to achieve desired properties such as resistance to extreme temperatures or chemical substances. On the other hand, molded silicone provides flexibility in design and allows intricate shapes to be produced.

Characteristics:

– Excellent Heat Resist Silicone o rings ance: Silicone o-rings can withstand extreme temperatures ranging from -60°C (-76°F) to 230°C (446°F), making them suitable for various environments.

– Chemical Compatibility: These seals exhibit exceptional resistance against solvents Rubberized silicone rings , oils, fuels, acids,

and bases – expanding their potential uses across numerous industries.

– High Flexibility: Silicon gaskets are known for retaining elasticity even after extended periods of use,

making them excellent at maintaining optimal seal integrity.

– Surface Protection: Silicone’s soft texture ensures that it won’t damage contacting surfaces while providing reliable sealing capabilities.

Advantages:

1. Versatility: Liquid silicone gaskets cater to various applications due to their adaptability and availability in different sizes.

2. Cost Effi Silicone o rings ciency: Silicone o rings offer a long service life cycle reducing replacement costs significantly over time compared to alternative solutions.

3. Easy Installation & Maintenance+: Their simple installation process enables anyone to replace these components without any specialized tools or skills required.

4.Broad Industry Range Usage+: Due to excellent che Collapsible Silicone Dog Bowl mical compatibility trait; they find application in automotive parts assembly,

Usage Methods:

To ensure proper utilization of silicone o-rings follow these steps:

1 Silicone Spatulas . Clean and lubricate the mating surfaces.

2. Use appropriate sealants or adhesives, if required.

3. Gently press-fit the o-ring into the groove ensuring it’s free from twists or folds.

4. Securely tighten mating surfaces to compress the silicone ring adequately.

Tips for Selecting Silicone O Rings:

To select the right silicone o rings, consider these essential factors:

1. Specific Application: Determine temperature range, chemical compatibilit

y requirements and pressure conditions of your application.

2. Material Hardness: Choose an o-ring with suitable hardness – measured in Shore A durometer – based on sealing effectiveness needs.

3.Dimension & Size Accuracy+: Accurate measurement of groove width ensures a perfect fit, preventing leaks or failure during operation.

Conclusio

n:

Silicone kitchen products have gained immense popularity due to their advantages over conventional materials such as rubber or metal-based seals.They offer superior heat resistance along with excellent flexibility and are compatible with various chemicals.These characteristics make them ideal for applications where reliable sealing is cruc Molded silicone rings ial.Since they can be easily installed and maintained without specialized skills, versatile silicone o-rings continue to play a vital role in different industries worldwide.Choos Silicone o rings ing quality silicone o rings tailored precisely to application requirements is paramount for ensuring optimal performance.In conclusion,silicone O rings provide exceptional reliability, durability, cost-efficiency,and long-lasting performance across diverse industries today.