Rigid-Flex PCB: The Future of Flexible Circuitry

Introduction:

In today’s rapidly evolving technological landscape, the demand for smaller and more efficient electronic devices is on the rise. As a result, innovative solutions must be developed to address the challenges posed by limited space and complex designs. One su Stiff-yet-pliable circuitboard ch solution is Rigid-flex PCB (Printed Circuit Board), which combines the best features of inflexible-yielding printed wiring boards with solid-flexible circuitry panels and stiff-yet-pliable circuit boards.

Manufacturing Process:

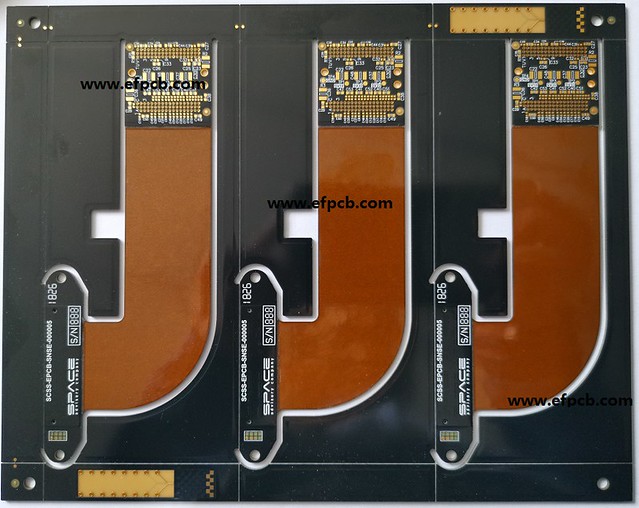

Rigid-flex PCBs are made using a combination of traditional rigid board materials along with flexible polyimide materials. This unique Inflexible-yielding printed wiring board combination allows for both flexibility and rigidity in one design, making it ideal for intricate electronic applications. The manufacturing process involves laminating alternating layers of copper traces and insulating materials onto a flexible substrate before adding additional rigid layers where needed.

Ke PCB supplier y Features:

The key feature that sets Rigid-flex PCBs apart from traditional circuit boards is their ability to bend without compromising performance or reliability. This flexibility enables designers to create highly compact devices while maintaining signal integrity across different sections of the board. Additionally, these boards offer excellent resistance against vibration, shock, and environmental factors due to their solid construction.

Advantages:

There are several advantages offered by Rigid-flex PCBs over conventional alternatives:

1) Space- PCBA Coating saving: With their ability to eliminate bulky connectors and cables, Rigid-flex PCBs allow for significant space savings within electronic systems.

2) Enhanced Reliability: By eliminating interconnect issues associated with cable assemblies or connectors, these boards enhance reliability while reducing failure points.

3) Improved Signal Integrity: The elimination of separate connections b

etween rigid portions improves signal transfer quality.

4) Cost-effective Manufacturing: Although initially costlier than standard rigid circuits or Rigid-flex PCB flex circuits individually assembled together as an assembly,the overall reduction in assembly steps can lead to lower manufacturing costs.

Usage Methodology:

To utilize Rigid-flex PCBs effectively, it is essential to follow some best practices:

1) Understand Design Constraints: Rigid-flex designs require careful consideration of bending areas and component placement. It is necessary to ensure that sensitive parts are not subjected to excessive strain during operation.

2) Collaborate with an Experienced PCB Supplier: Working closely with a reputable and experienced supplier specializing in Rigid-fle Ceramic PCB x PCB solutions ensures high-quality products that meet design requirements.

Selecting the Right Product:

When selecting a Rigid-flex PCB for your project, consider the following factors:

1) Manufacturing Capabilities: Ensure that the chosen supplier has sufficient capabilities to manufacture the desired rigid-flex board design flawlessly.

2) Certifications and Standards: Check if any industry-specific certifications or standards compliance is required for your application.

Conclusion:

Rigid-Flex PCBs have revolutioni Rigid-flex PCB zed modern electronic design by offering a unique combination of flexibility and rigidity. Their ability to withstand challenging environments while reducin Rigid-flex PCB g space requirements makes them ideal for numerous applications across industries such as aerospace, medical devices, automotive electronics, and more. By understanding their manufacturing process, key features, advantages, usage methodology, selection criteria; engineers can harness the full potential of these innovativ Solid-flexible circuitry panel e boards in their upcoming projects giving rise to highly efficient electronic systems.

As technology continues its relentless march forward,Rigid-Flex PCB remains at the forefront of next-generation printed circuit board technology due to its undeniable benefits over traditional alternatives. Celebrated for their adaptability,growing demands for compactness together with desiref

or improved performance make clear indications about increased acceptance of these circuits.Considering all relevant aspects will allow engineers access to efficient,reliable,and cost-effective equipment ensuring seamless integration into future technologies. Let us embrace this technological marvel as we step confidently into an era where flexibility meets rigidity!