PCBA Coating: Protecting the Circuit Board Assembly

Intr Printed circuit board assembly coating oduction

In today’s fast-paced technological world, circuit board assembly protection has become a critical aspect in ensuring the longevity and reliability of electronic devices. One method commonly used in this process is PCBA coating, which involves applying a protective layer to the printed circuit boards (PCBs). This article explores the manufacturin PCBA Coating g process, features, advantages, usage methods, tips for selecting PCBA coatings, and concludes with insights into this essential component of modern electronics.

Manufacturing Process

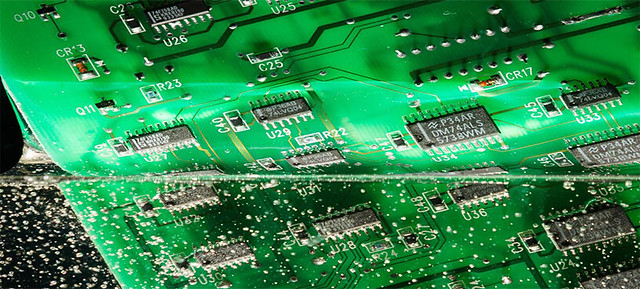

The PCB assembly coating process begins after solder mask application. Once all components have been mounted on the completed PCBs through intricate assembly processes, it is time to protect them from various environmental factors. The coatings are typically applied using specialized equipment that ensu Circuit board assembly protection res uniform coverage without damaging or interfering with the assembled components.

Features

PCBA coating offers several crucial features that enhance its effectiveness as a means of protecting PCBA Coating circuit board assemblies. Firstly, it provides an insulation barrier against moisture and dust particles that can cause corrosion or short-circuiting. Additionally, these coatings offer excellent chemical resistance properties to safeguard sensitive electronic elements from harmful substances present within their operational environments.

Adva Solder mask application ntages

Using PCBA coatings yields numerous advantages for manufacturers and end-users alike. First and foremost, they prolong product lifespan by shielding PCBs from harsh external factors such as humidity or temperature variations. Moreover, these coatings improve overall reliability since they act as an extra layer of defense against unforeseen circumstances like accidental spills or oxidation due to long-term exposure.

Usage Methods

To apply PCBA coa PCBA Coating ting effectively requires adherence to specific usage methods recommended by industry professionals. Manufacturers should ensure

appropriate surface preparation before initiating the actual application process by thoroughly cleaning any contaminants present on assembled modules’ surfaces. Then comes precise masking around connectors and sensitive areas where no coating is desired; precision here ensures optimal functionality while maximizing protection.

Tips for Selecting PCBA Coatings

When faced with choosing a suitable PCBA coating, a few essen PCB Assembly tial factors must be considered. First and foremost, the coating material’s compatibility with the specific PCB design and assembly components should be thoroughly evaluated. High-quality coatings that meet industry standards and have proven records of performance are ideal choices to ensure lasting protection.

Conclusion

PCBA coating plays a pivotal role in safeguarding circuit board assemblies from po PCBA Coating tential damage caused by various external factors. Manufacturing processes, such as solder mask application, coupled with the use of dependable protective coatings like PCB assembly coatings, significantly contribute to enhancing product reliability and PCB Assembly longevity. By understanding their features, advantages, usage methods, and how to choose appropriate PCBA products effectively can manufacturers guarantee optimal protection for their electronic devices.