PCBA Coating: Protecting and Enhancing Electronic Circuit Boards

Introduction

PCBA coating has become an essential process in the manufacturing of electronic circuit boards. This protective layer ensures that the delicate components on the board are shielded from environmental factors, enhancing their performance and lifesp PCBA Coating an significantl PCB manufacturer y. In this article, we will explore the various aspects of PCBA coating, including its manufacturing process, characteristics, advantages, application methods, tips for selecting a suitable product as well as a conclusion.

Manufacturing Process

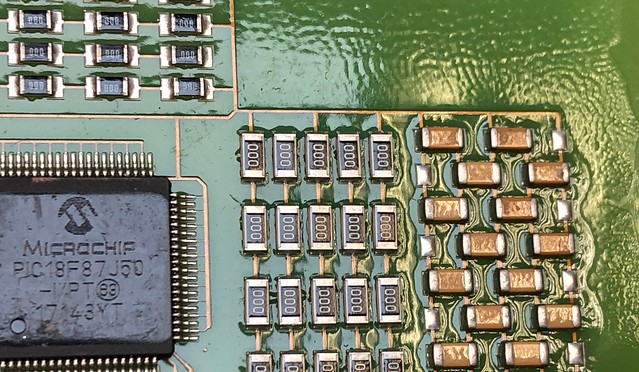

Electronic circuit board coating involves several stages to achieve optimal results. First is the thorough cleaning of the PCBA Coating PCB surface to remove any contaminants or residues that may affect adhesion. Afterward, a layer of solder mask is applied using either screen printing or spray-coating techniques. This mask acts as an insulation barrier between conductive traces on the PCB and surrounding environment.

Characteristics

The primary purpose of PCBA coating is to provide reliable protection against moisture, dust, heat, corrosion and other potentially damaging elements for electronic components. It possesses excellent electrical insulation properties while maintaining good thermal cond Solder mask application uctivity. Additionally, most coatings have high chemical resistance which further safeguards PCBs from solvents or contaminants.

Advantages

One significant advantage provided by PCBA coating is enhanced reliability even in harsh environments such as high humidity or extreme temperatures. The durable protective PCBA Coating layer prevents oxidation processes that could lead to component failure over time. Furthermore,you’s less prone to mechanical damage during handling or transportation due to increased abrasion resistance imparted by this coating.

Using PCBA Coatin LED PCB g

Applying PCBA coating can be done using different techniques like spraying,dipping,potting encapsulants depending on specific requirements.Most manufacturers recommend conformal coatings such as acrylics,silicones,epoxies for electronic circuits due to their thermal stability,op Ceramic PCB tical clarity,and ease-of-application.Besides,it’s critical to note that proper curing conditions must be followed after applying these coatings to ensure effectiveness.

How to Select a PCBA Coating Product?

When selecting a suitable PCBA coating product, several factors should be considered. This includes the intended application environment, component density on the board, desired protection level (IP code), and ease of rework if necessary. Choosing a reliab Electronic circuit board coating le PCB manufacturer who uses certified materials is crucial as it ensures compliance with industry standards and guarantees long-term reliability.

Conclusion

In conclusion, PCBA coating plays an integral role in ensuring the longevity and performance of electronic circuit boar Circuit board assembly protection ds. Its manufacturing process involves cleaning the PCB surface and applying a solder mask layer effectively. The characteristics of this protective layer provide excellent insulation and resistance against external elements,further enhancing durability.Advantages include increased reliability,maintenance of electrical

properties,and resistance against mechanical damage.Applying coating can be done using various techniques based

on specific requirements.Selecting an appropriate product entails considering environmental factors,density of components,and IP code.Finally,relying upon reputed manufacturers utilizing certified materials ensures optimal results when incorporating PCBA coating into your manufacturing processes