PCBA Coating: Enhancing Surface Protection for Electronic Components

Introduction:

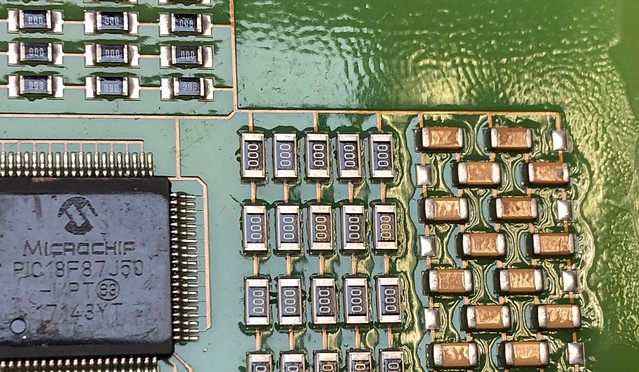

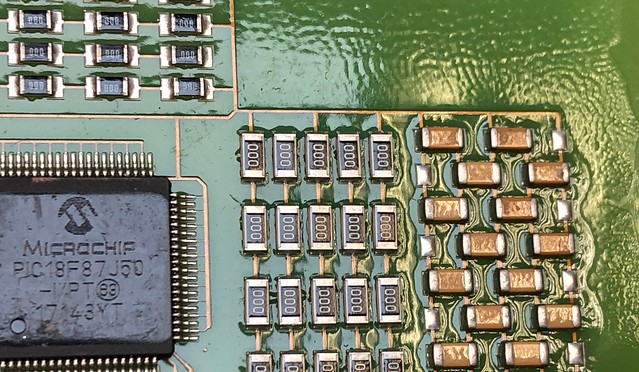

In the world of electronic components, surfa

ce protection is crucial to ensure their long-term functionality. One popular method used in the industry is PCBA coating, which provides a layer of protection against external factors such as moisture, dust, and chemicals. In this article, we will explore the manufacturing process, features, advantages, usage methods and tips on selecting PCBA coating.

Manufacturing P Aluminum PCB rocess:

PCBA coating involves applying a thin protective layer onto printed circuit board assemblies (PCBAs). This can be achieved through various techniques including spray coating or selective conformal coating. The cho Surface protection for electronic components sen method depends on factors like component layout complexity and desired level of protection.

Features:

Component-level encapsulation is a primary feature of PCBA coatings. By covering each electronic component individually with a protective fi

lm, it ensures an extended lifespan for these components. Additionally,

the PCBAs become more resistant to environmental stressors like temperature fluctuations and humidity.

Advantages:

The use of PCBA coatings offers several advantages over traditional methods of surface protectio PCBA Coating n for electronic components:

1. Improved Reliability: The added layer shields sensitive electrical parts from corrosion and mechanical damage caused by environmental elements.

2. Enhanced Durability: PCBA coatings provide excellent resistance against moisture penetration that can lead to short circuits or functional failures.

3. Increased Safety: With proper in PCBA Coating sulation provided by the coatings, there is lower risk of electrical shock hazards.

Usage Methods:

To apply PCBA coatings effectively,

1.Start by thoroughly cleaning all surfaces using approved solvents to remove any impurities or residues.

2.Select an appropr Component-level encapsulation iate application technique based on your specific requirements (e.g., spray application for large quantities vs.conformal dip).

3.Ensure uniformity by using automated systems or professional service providers when needed.

4.Allow sufficient curing time as recommended by th Smart door lock supplier e manufacturer before proceeding with assembly or further handling processes.

How to Choose the Right Product:

When selecting a PCBA coating, consider the following factors:

1. Environmental Compatibility: Ensure the chosen product can withstand the intended operating conditions (e.g., temperature range, humidity levels).

2. Component Type: Different coatings are designed for spe

cific component types (e.g., aluminum PCBs, ceramic PCBs). Select one that suits your particular needs.

3. Application Method: Assess whether spray coating or selective conformal coating is more suitable for your production line and target cos Printed circuit board assembly coating t.

Conclusion:

PCBA coatings offer an effective solution for protecting electronic components from external elements and prolonging their lifespan. With features such as component-level encapsulation and enhanced durability, these coatings provide numerous advantages over traditional protection methods. By understanding the manufacturing process, usage methods,

and factors to consider when choosing a product, manufacturers and users alike can harness the benefits of PCBA coatings in their electronic a Ceramic PCB ssemblies.

Keywords:

Tit PCBA Coating le: PCBA Coating – Enhancing Surface Protection for Electronic Components

Component-level encapsulation,Surface protection for electronic components,

Printed circuit board assembly coating,Board level conformal coating,

PCBA CoatingSmart door lock supplierAluminum PCB,Ceramic PCB