PCBA Coating: Advantages and Applications

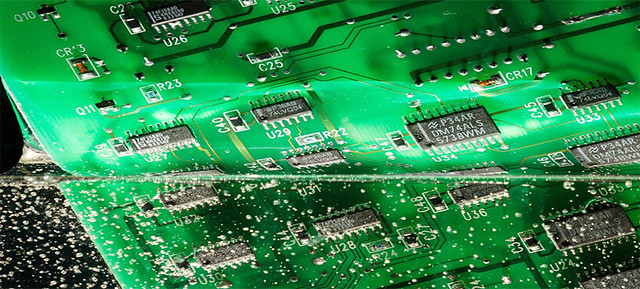

PCBA coating, also known as printed circuit board assembly coating, is a crucial process in the manufacturing of electronic compon PCBA Coating ents. This surface protection method plays a vital role in ensuring the longevity and reliability of PC PCBA Coating B assemblies. By applying a protective layer to the PCB, it helps prevent damage from environmental factors such as moisture, dust, and chemicals.

One popular method for PCBA coating is

solder mask application. This involves applying a layer of material over the assembled circuit board to protect it from corrosion an Printed circuit board assembly coating d mechanical damage. Another common technique is board level conformal coating, which provides an extra layer of insulation against moisture and other contaminants.

The use of PCBA coating offers several advantages. It improves the overall durability of electronic components by providing a barrier against external elements. Additionally, it h Surface protection for electronic components elps reduce the risk of short circuits and electrical malfunctions caused by en Aluminum PCB vironmental factors. Furthermore, PCBA coatings can enhance the aesthetic appeal of circuit boards by adding color or texture to them.

When selecting a PCBA coating product, it’s essential to consider factors such as compa

tibility with your specific application requirements and ease of application. Smart door lock suppliers often utilize PCBA coatings to improve the performance and longevity of their products. In addition, materials like aluminum PCBs or ceramic PCBs can benefit greatly f PCBA Coating rom proper coating techniques.

In conclusion, PCBA coating play Ceramic PCB s a critical role in enhancing the reliability and lifespan of electronic components. With its numerous benefits and applications in various industries, this surface protection method remains an essential aspect

of modern manufacturing processes.

By incorporating key terms such as “PCB assembly coating,” “Surface protection for electronic components,” “Printed circuit board assembly

coating,” “Solder mask application,” Board level conformal coating; along with ”Smart door lock supplier” ,” Smart door lock supplier Aluminum PCB” ,”Ceramic

PCB”; this article highlights ess PCB assembly coating ential information about PCAB Coatings while emphasizing its importance when considering proper surface

protection methods for electronic components production.