Aluminum PCB: The Versatile and Reliable Choice for Your Electronic Needs

Introduction:

In today’s rapidly evolving technological landscape, the demand for efficient and reliable printed circuit boards (PCBs) continues to rise. Among the various types available, Aluminum PCBs have emerged as a popular choice Aluminium-based PCB due to their exceptional performance in diverse applications. This article aims to delve into the manufacturing process, characteristics, advantages, usage methods, tips for selecting this product, and conclude with a summary of their significance.

Manufacturing Process:

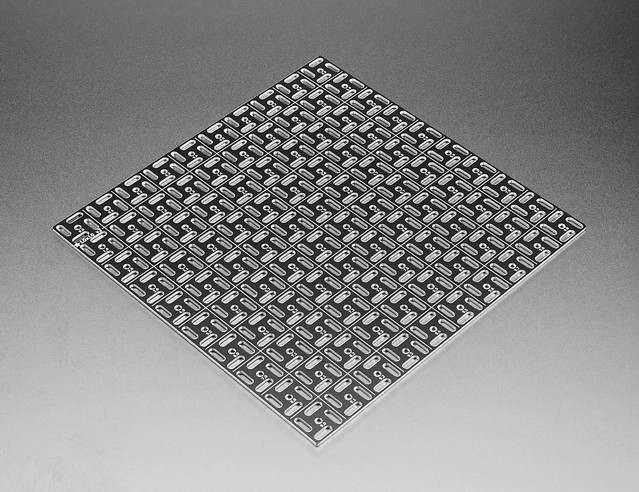

Aluminum PCBs are manufactured Aluminum PCB manufacturer using advanced technology that involves layering a thin copper conductor on top of an aluminum substrate board. The layered structure is achieved either through etching or thermal cladding techniques. These processes ensure strong adhesion between layers while allowing effective heat dissipation.

Characteristics:

MCPCB (Metal Core Printed Circuit Board), also known MCPCB (Metal Core Printed Circuit Board) as Aluminium-based PCB or Alu-PCB at times, possesses several unique characteristics that set it apart from other variants. Firstly, its excellent thermal conductivity enables superior heat dissipation properties compared to traditional FR4 boards. This makes them ideal for high-power applications where temperature management is critical.

Secondly, the

ir low operating temperatures contribute significantly to extended product lifespan by reducing stress on components.

Lastly but importantly,the metal base provides enhanced mechanical strength and vibration resistance – crucial attributes required in harsh environments.

Advantages:

The integration of Alumi Aluminum PCB num substrates in electronic devices brings forth a multitude of advantages:

1) Enhanced heat transfer capabilities increase power density and allow compact designs.

2) Increased reliability due to reduced risk of overheating-related failures.

3) Better s Aluminum PCB manufacturer ignal stability through decreased impedance caused by temperature changes.

4) Lightweight nature beneficial in portable devices which require weight op

timization.

Usage Methods:

Aluminum PCBs find wide-ranging applications across multiple industries including automotive electronics,solar energy systems,

LED lighting solutions,and telecommunications,to name just a few.Their ability to withstand extreme temperatures,maintain signal integrity,and dissipate power efficiently makes them s Flexible PCB manufacturer uitable for both small and large-scale projects.

How to Select the right Aluminum PCB Manufacturer:

Choosing a reliable Aluminum PCB manufacturer is paramount to ensure product quality and performance. Here are a few key factors to consider during your selection process:

1) Experience: Look for experienced manufacturers with proven track records in producing high-quality boards.

2) Certification: Check if the manufacturer complies with industry standards and holds relevant certifications such as ISO 9001.

3) Te Aluminum PCB chnical Capabilities: Evaluate their equipment, facilities, and manufacturing processes to gauge their ability to meet your specific requirements.

4) Aluminum PCB Customer Reviews: Seek feedback from previous clients regarding delivery times, responsiveness, and overall satisfaction.

Conclusion:

In conclusion, Aluminum PCBs have revolutionized the electronics industry by providing superior thermal management properties that enhance reliability while maintaining compactness. The unique characte

ristics of these boards enable efficient heat dissipation, reduced risk of overheating-related failures, improved signal stability, and decreased impedance caused by temperature variations. When selecting an Aluminum PCB manufacturer,factors such as experience,certification,and technical capabilities should be considered.Given their wide-ranging applications across various industries,it is evident that Alumi Aluminum substrate board num PCBs play a vital role in shaping our technological advancements. Embracing this cutting-edge technology ensures uncompromised performance,making it an ideal choice for engineers seeking innovative solutions.