Aluminum PCB – The Ultimate Choice for High-Quality Electronics

Introduction:

In today’s fast-paced world, technology is advancing at an unprecedent Aluminum PCB manufacturer ed rate. With the increasing demand for compact and efficient electronic devices, manufacturers are constantly seeking innovative solutions to meet consumer needs. One such solution that has gained immense popularity in recent years is Aluminum Printed Circuit Board (PCB), also known as Al-PWB.

Manufacturing Process of Aluminum PCBs:

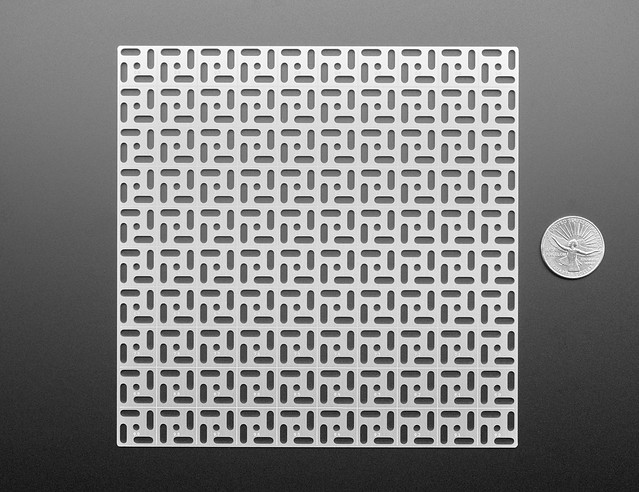

Aluminum PCBs are manufactured using a specialized process that involves laminating a thin layer of aluminum onto a non-conductive substrate, typically made of fiberglass or ceramic m Aluminium-based PCB aterials. This layer acts as a reliable heat dissipater, making it ideal for applications where efficient thermal management is crucial.

Characteristics and Advantages of Aluminum PCBs:

1. Heat Dissipation: The primary advantage of Aluminum PCBs is MCPCB (Metal Core Printed Circuit Board) their exceptional ability to dissipate heat quickly and effectively compared to traditional FR4 boards. This characteristic makes them perfect for high-power electronic components and applications such as LED lighting systems, power supplies, automotive electronics, etc.

2. Lightweight & Cost-effective: Due to being constructed primarily fr Aluminum PCB om lightweight aluminum material instead of copper-based substrates, these boards offer significant weight reduction advantages without compromising performance or reliability. Additionally, they prove cost-effective due to reduced material expenses during the manufacturing process.

3. Enhanced Durability: Another distinguishing feature of Aluminum PCBs lies in their structural integrity. They exhibit excellent dimensional stability even under extreme environmental conditions like high temperatur Aluminum PCB es or humidity levels, ensuring long-term reliability.

Methods of Using Aluminum PCBs Effectively:

To utilize the full potential offered by Aluminum PCBs effectively:

– D Aluminum PCB esign thermal pads properly beneath power components.

– Ensure adequate airflow around the board.

– Optimize routing patterns for better heat distribution.

– Implement effective cooling mechanisms such as heatsinks if necessary.

How to Choose an Ideal Manufacturer:

When selecting an ideal manufacturer for your desired Al-PWB requirements:

1. Experience: Look for Al-PWB (Aluminum Printed Wiring Board) a manufacturer with ample experience in producing Aluminum PCBs to ensure high-quality production practices.

2. Certification: Ensure that the manufacturer has necessary certifications such as ISO 9001, UL, RoHS compliance, etc., indicating their commitment to product quality and safety standards.

3. Customization Options: Opt for a manufacturer who can provide customized designs according to your s

pecific project requirements.

Conclusion:

In conclusion, Aluminum PCBs have revolutionized the electronics industry by offering excellent heat dissipation capabilities, lightweight construction, and enhanced durability. Whether you are designing power electronics or LED lighting Aluminum PCB manufacturer systems, Al-PWB is an ideal choice due to its exceptional thermal management properties and reliability.

When choosing an Aluminum PCB manufacturer, consider factors like experience, certifications obtained by the company ensuring adherence to international quality standards along with customization options available.

By opting for high-quality Aluminum PCBs from reputable manufacturers equipped with cutting-edge technologies and stringent quality control measures like flexib Flexible PCB manufacturer le PCB manufacturers , you can guarantee superior performance and longevity of your electronic applications. So make yourself future-ready by embracing this versatile technology today!