Aluminum PCB Aluminum PCB: The Future of Printed Circuit Boards

Manufacturing Process:

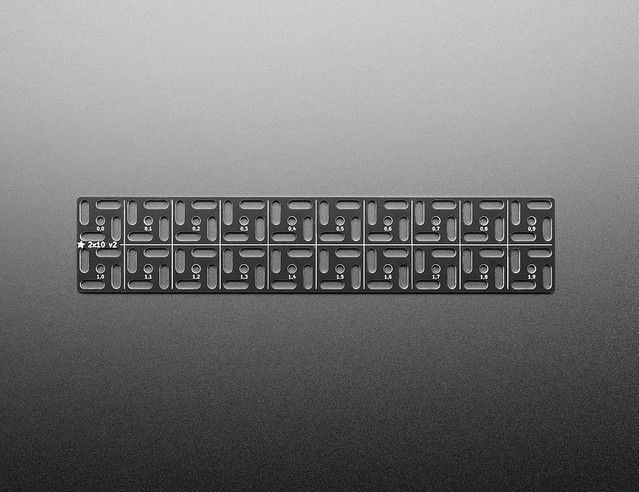

Aluminum PCBs, also known as Aluminium-based PCBs or Alu-PCBs, are manufactured using a specialized process that involves the use of an aluminum substrate board. This board is clad with a layer of aluminum to provide both structural integrity and excellent thermal conductivity. The circuitry is then Aluminum PCB manufacturer created on top of this aluminum layer using standard printed circuit board manufacturing techniques.

Key Features:

One of the key features of Aluminum PCBs is their superior heat dissipation capabilities. Due to the highly conductive nature of aluminum, these boards can efficiently transfer heat away from sensitive

components, ensuring optimal performance and reliability in high-power applications. Additionally, Aluminum PCBs offer excellent rigidity and durability, making them resistant to mechanical stress and environmental factors such as humidity.

Advantages:

The u Aluminum PCB se of Aluminum PCBs offers several advantages over traditional epoxy-based FR4 boards. Firstly, their ability to dissipate heat effectively allows for smaller form factors and higher power densities in electronic designs. Secondly, the lightweight nature of aluminum makes these PCBs ideal for portable devices where weight reduction is crucial. Furthermore, the enhanced mechanical properties reduce the risk of failure due to thermal expansion or vibration.

Usage Methods:

Aluminum clad PCBs find Aluminum PCB extensive use in industries such as automotive electronics, LED lighting systems,

power supplies,frequency converters,and telecommunications equipment.

These boards are particularly suitable for applications requiring high-power output or those operating in harsh environments where temp Aluminum PCB manufacturer erature management is critical.

Choosing the Right Product:

Whe Aluminum substrate board n selecting an Aluminum PCB manufacturer,factors like experience,customer support,supplier reputation,and quality control processes should be considered.It’s essential to verify if a manufacturer has expertise in producing reliable Aluminum-PBC productsthat meet your specific requirements.Flexibility,multiple layers options,and adherence

to industry standards must also be taken into account.Investing time upfront can lead to cost savings,durability ,and enhanced performance in the long run.

Conclusion:

Aluminum P Flexible PCB manufacturer CBs have revolutionized the field of printed circuit board technology with their superior thermal conductiv Aluminium-based PCB ity and mechanical properties. Their ability to efficiently dissipate heat opens up new possibilities for high-powered electronic designs. Whether it’s automotive applications, LED lighting, or power supplies, Aluminum PCBs offer a reliable solution that ensures optimal performance and durability. Selecting a reputable manufacturer is crucial for obtaining high-quality boards that meet your specific needs. Embrace this advanced technology and u Alu-PCB (short form) nlock the full potential of your electronic designs with Aluminum PCBs.