Aluminum PCB: Manufacturing, Features, Advantages, and Selection Guide

Introduction:

In the world of printed circuit boa

rds (PCBs), Aluminum PCBs have gained significant popularity due to their exceptional thermal conductivity properties. This article will delve into various aspects of Aluminum PCBs including manufacturing methods, characteristics, advantages, usage guidelines, tips for selectin Aluminum PCB g a reliable manufacturer, and a concise conclusion.

Manufacturing Methods:

Aluminum-based PCBs are manufactured using several different methods such as etching or subtractive method and additive method. The etching method involves removing unwanted copper from the board usin Aluminum PCB manufacturer g strong chemicals while leaving behind the desired circuitry. On the other hand, the additive method builds up traces by depositing conductive materials onto an insulating substrate.

Characteristics:

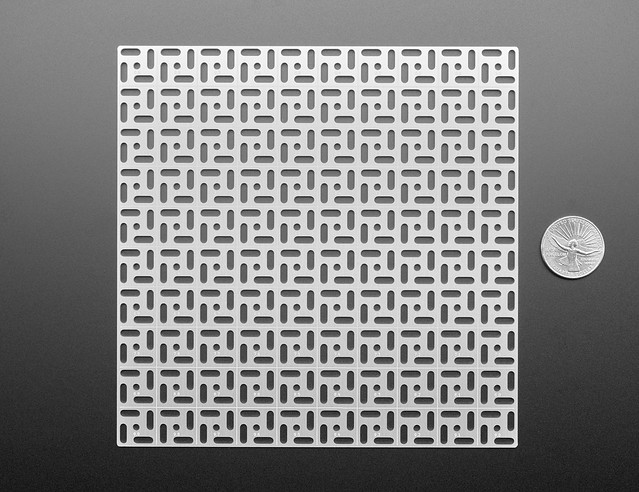

Aluminum-based PCBs possess some distinct characteristics that set them apart from traditional FR4 boards. They are lightweight yet durable due to the use of aluminum as a base material. The high thermal condu Alu-PCB (short form) ctivity of aluminum allows for efficient heat dissipation which is essential in applications where excessive heat generation is expected. Additionally, these boards offer excellent electrical performance with low impedance levels.

Advantages:

The key advantages of Aluminum PCBs include their ability to Flexible PCB manufacturer handle high-power loads effectively without overheating issues. Their impressive heat dissipation capabilities make them suitable for LED lighting applications where temperature management is crucial for optimal performance and longevity. Furthermore, their compac Aluminum PCB t size and reduced weight provide design flexibility and ease of integration into space-constrained electronic devices.

Usage Guidelines:

When utilizing Aluminum PCBs in your projects or products:

1) Ensure proper insulation between power traces: Since aluminum conducts electricity efficiently like any metal surface would do when not insulated properly; it’s necessary to maintain adequate spacing between high-voltage tracks.

2) Consider mechanical stability: Due to its lightweight nature compared to conventional substrates l Aluminum PCB manufacturer ike FR4 or ceramic materials; additional care should be taken when mounting heavy components on MCPCB (Metal Core Printed Circuit Board) Aluminum-based boards.

3) Implement proper thermal management: Aluminum PCBs require effective heat sinking techniques to enhance their performance by preventing overheating. Incorporating heat sinks, vias, and proper ventilation are recommended practices.

How to Select a Reliable Manufacturer:

When considering an Aluminum PCB manuf

acturer:

1) Look for experience and expertise: Consider manufacturers with extensive experience in producing high-quality Aluminum PCBs for various industries.

2) Check production capabilities: Verify if the manufacturer has state-of-the-art facilities and equipment necessary to ensure precise manufacturing processes.

3) Aluminium-based PCB Request sample boards: Inspecting sample boards will provide insights into the quality of their workmanship and adherence to design specifications.

Conclusion:

Aluminum-based PCBs offer numerous advantages over traditional circuit boards, making them an attractive choice for applications where effective heat dissipation is critical. By understanding their manufacturing methods, characteristics, advantages, usage guidelines, and selecting a reliable manufacturer; engineers can confidently incorpora Aluminum PCB te Aluminum PCBs into their designs while achieving optimal functionality and performance.