Aluminum PCB: A Comprehensive Guide

Introduction

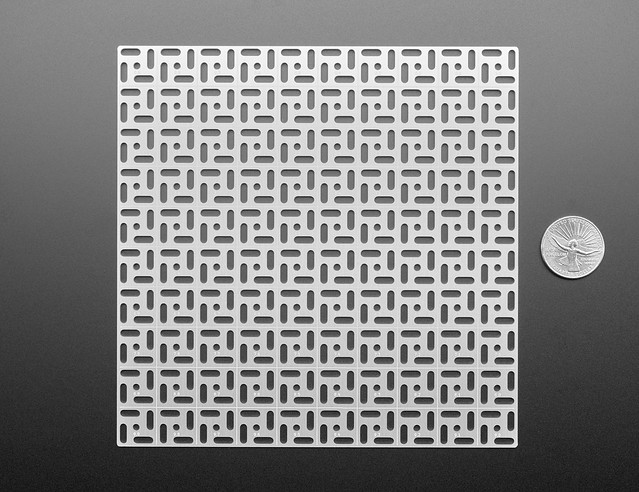

Aluminum PCBs (Aluminium-based PCBs) are an essential component in the electronics industry. This article aims to provide a detailed analysis of the manufacturing process, characteristics, advantages, usage methods, tips for selecting this product, and a conclusi Aluminium-based PCB on.

Manufacturing Process

The production of Aluminum PCBs involves several key steps. Firstly, a layer of aluminum is chosen as the base material for its exceptional thermal conductivity. Then, a thin layer of dielectric material is laminated on top to insulate and protect the circuitry. Next, a copper foil is added to creat Flexible PCB manufacturer e electrical pathways using etching or deposition techniques. Finally, the protective solder mask and silk screen legend layers are applied.

Characteristics

Aluminum substrate boards possess unique characteristics that make them highly de Aluminum PCB manufacturer sirable in various applications. These include their superior heat dissipation capabilities due to high thermal conductivity properties compared to traditional FR4 boards. Th MCPCB (Metal Core Printed Circuit Board) e lightweight nature of Aluminum PCBs makes them ideal for portable devices where weight reduction is crucial. Additionally, these boards offer excellent dimensional stability and rigidity while maintaining good electrical insulation properties.

Advantages

The use of MCPCB (Metal Core Printed Circuit Board), also known as A-PCB (Aluminum PCB) or Alu-PCB (short form), offers several advantages over other ty Aluminum PCB pes of circuit boards. First and foremost is its efficient heat dissipation ability which ensures optimal performance even under intense operating conditions. The low thermal resistance enables prolonged lifespan and prevents overheating issues commonly encountered with non-metal core substrates.

Usage Methods

When using Aluminum PCBs effectively in electronic designs, it’s importan Aluminum PCB private label t to consider their specific application requirements such as power density levels or environmental factors like temperature fluctuations or vibrations precautionary measures must be taken during assembly not exceeding recommended temperatures so as not induce excessive stress on components ensuring reliable conn Aluminum PCB ections throughout.

How to Select Aluminum PCB Products?

Choosing the right Aluminum PCB product is crucial for successful implementation. Considerations should include the reliability of the manufacturer, their experience in producing high-quality products, certifications obtained (such as ISO 9001), and adherence to industry standards (like IPC-A600). Furthermore, assessing the manufacturer’s ability to provide value-added services such as design support, prototyping options, or custom sp Aluminum PCB ecifications can significantly influence decision-making.

Conclusion

Aluminum PCBs offer an excellent solution for applications requiring efficient heat dissipa Aluminum substrate board tion and lightweight design. With superior characteristics and numerous benefits over traditional circuit boards, Aluminum PCBs have become increasingly popular in industries ranging from automotive electronics to LED lighting fixtures. By understanding the manufacturing process, key properties, advantages, usage methods, and tips for selecting this

product wisely from reliable manufacturers with quality control measures in place will undoubtedly contribute to achieving overall project success.

In conclusion,: let us embrace the future opportunities that Aluminum PCB holds while innovating and evolving towards more advanced technologies.