Alloy Steel Plate: The Ultimate Guide

Introduction:

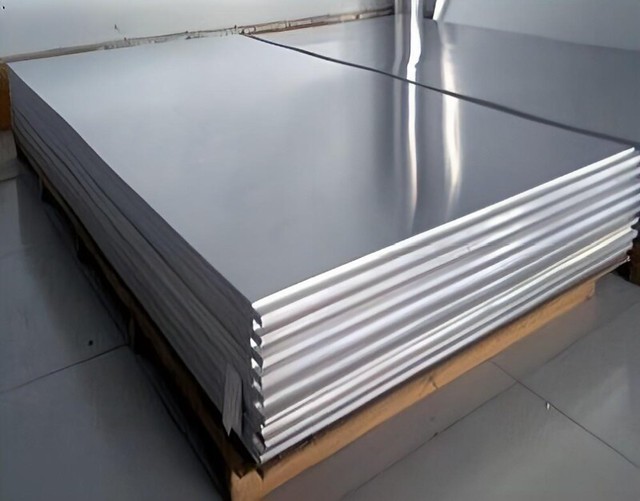

In the world of manufacturing, alloy steel plate plays a vital role. From its unique blend to its remarkable strength, alloy steel plate this compound alloy panel has become an essential material in various applications. In this comprehensive guide, we will explore the making process, characteristics, advantages, usage methods, tips for selecting the right product and conclude on why alloy steel plates are an ideal choice.

Making Process:

The production o Blend steel plate f alloy steel plates involves a complex manufacturing process. It begins with the selection of high-quality raw materials such as Mixed Metal Sheet which contains different metals like iron, titanium, chromium and more. These metals undergo a series of heating and cooling processes known as tempering or quenching alloy steel plate to ensure maximum hardness and durability. Finally, they are shaped into large sheets through a combination of rolling and pressing techniques.

Characteristics:

Alloy steel plates possess several key characteristics tha

t make them highly sought after in numerous industries. Firstly, their exceptional strength enables them to withstand intense pressure without any signs of deformation or damage. Additionally, their superior corrosion resistance properties make them resistant to rusting even when exposed to harsh environments for extended periods.

Advantages:

Ther Compound alloy panel e are several notable advantages associated with using alloy steel plates. First and foremost is their ability to handle high temperatures without losing structural integrity—a crucial feature for applications such as construction machinery or boilers that require heat resistance. Secondly is their unmatched impact resistance which guarantees protectio alloy steel plate n against heavy impact forces under extreme conditions.

Usage Methods:

The versatility of alloy steel plates allows them to be used in diverse industries ranging from automotive manufacturing to aerospace engineering.

In construction projects where load-bearing capacity is paramount,

blend-steel plate comes into play due to its excellent mechanical properties.

Compound Alloy Panel can also be applied in situations requiring lightwe

ight but strong materials like shipbuilding or vehicle bodies.

Composite Steel Plate finds extensive use in industrial equipment where exceptional toughness is required,

such as mining machinery components or pressure vessels.

How to Select the Right Product:

When choosing an alloy steel plate, several factors should be taken into consideration. Firstly, it’s essen Carbon Steel Plate tial to determine the specific requirements of your project and select a plate that meets those needs precisely. Consider aspects such as strength, corrosion resistance, and heat

tolerance based on the intended application.

Evaluate the material’s certifications and standards compliance to ensure quality and safety.

Lastly, take into account factors like cost-effectiveness and availability from reputable suppliers before making a final decision.

Conclusion:

Alloy steel plates are revolutionizing various industries with their exceptional properties. The manufacturing process ensures high-quality sheets while their characteristics Carbon Steel Plate include unmatched strength and corrosion resistance.

With advantages such as temperature stability and impact resistance,

compound alloy panels have proven themselve alloy steel plate s in extreme conditions time after time. Whether it’s mixed metal sheet for structural constructions or composite steel plates for industrial applications,

the versatility of these products is invaluable in countless projects worldwide.

By following our guide on selecting the right product, you can make an informed choice suitable for your unique requirements.

In conclusion, alloy steel plates are here to stay as they continue to dominate num Mixed metal sheet erous sectors due to their superior performance qualities.