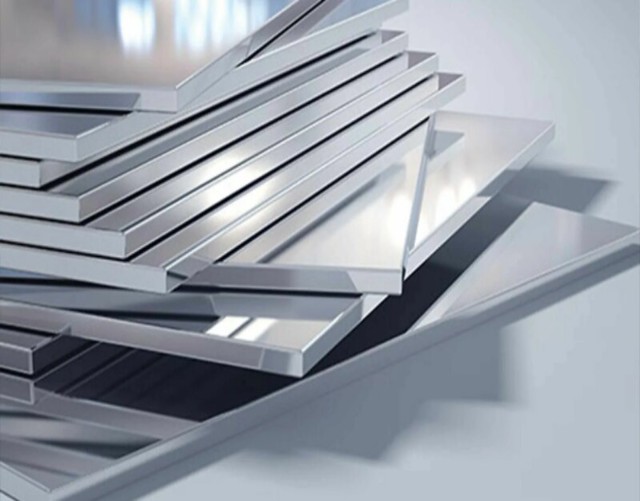

Alloy Sheet: An Essential Component in the World of Metal Plates

Introduction:

In today’s ever-evolving industrial world, alloy sheets have become a vital element in various applications. With their unique proper Steel sheet ties and versatility, these sheets play a significant role in manufacturing processes across different sectors. This article provides an in-depth understanding of alloy sheet production methods, characteristics, advantages, usage tips, and guidelines on selecting the right product.

Manufacturing Methods:

Alloy sheets are produced using various techniques depending on the Alloy Sheet desired specifications and project requirements. One commonly used method is cold rolling, where metal ingots are compressed between rollers at room temperature to form thin sheets. Another approach involves hot rolling which includes heating the metal plates bef Brass plate ore passing them through high-pressure rollers. These methods ensure consistency and uniformity throughout the sheet’s surface.

Characteristics:

Alloy sheets possess several essential characteristics that make them highly sought after in numerous industries. Firstly, they exhibit exceptional corrosion resistance due to

their composition entailing metals such as brass plate, steel sheet (including stainless steel), titanium alloy sheet etc., ensuring long-lasting performance even under harsh environmental conditions. Secondly, they offer excellent strength-to-weight ratios enabling structural stability while minimizing overall weight burdens.

Advantages:

The utilization of alloy sheets offers significant advantages over othe

r materials such as carbon steel plates or standard metal counterparts. Their notably high strength contributes to improved load-bearing capabilities making them ideal for heavy-duty applications like construction projects or aerospace components. Furthermore,their inherent tensile strength allows for easy forming and shaping without compromising durability.

Usage Tips:

To maximize efficiency when utilizing alloy sheets it is crucial to consider certain factors during installation or fabrication processes. Firstly,ensure proper handling Alloy Sheet by avoiding excessive bending or rough contact which may damage surface finishes; this could potentially compromise its corrosion resistance properties thereby reducing lifespan。Additionally,Stringent quality control during procurement stage ensures adherence towards required standards thus safeguarding against potential defects;this also prevents material inconsistencies leading to product failure. Regular maintenance such as c Titanium alloy sheet leaning with appropriate solutions and routine inspections contribute towards prolonging the lifespan of alloy sheets.

H High Strength Carbon Steel Plate ow to Select the Right Alloy Sheet:

Selecting the most suitable alloy sheet for a specific application involves careful consideration of various factors. Firstly, determine the required mechanical properties such as strength, ductility, or fatigue resistance based on project specifications;this aids in determining compatible alloys.Secondly,consider environmental exposures like moisture levels or corrosive agents; these factors influence material selection by dictating resistance levels.Finally,analyzing cost constraints relative to desired performance fuels efficient decision-making;while selecting premium-grade alloys may enhance quality assurance,it is i High Strength Carbon Steel Plate mportant t balance requi Alloy Sheet rements with economic feasibility.

Conclusion:

Alloy sheets have revolutionized numerous industries due to their superior characteristics and remarkable advantages over other materials primarily due their composition including brass plates, steel sheets (especially stainless), titanium alloy sheets etc.They offer exceptional strength, corrosion resistance,and versatility,making them an indispensable eleme Alloy Sheet nt in sectors ranging from construction to aerospace.Maintaining best practices during fabrication coupled with effective utilization ensures extended service life and optimal performance.As technology continues advancing,we can anticipate further innovations paving way for new applications while progressively enhancing existing operations