A Guide to PVC Card Suppliers

Distributor of plastic identification card printers, systems & supplies including RFID, magnetic stripe & smart cards. Provides ID system integration, software & repairs for major printer brands.

PVC cards are sturdier than paper cards, providing longer durability and reducing the need for frequent reprints. They are also compatible with most card printers, including direct-to-card and retransfer printers.

How to make a PVC card?

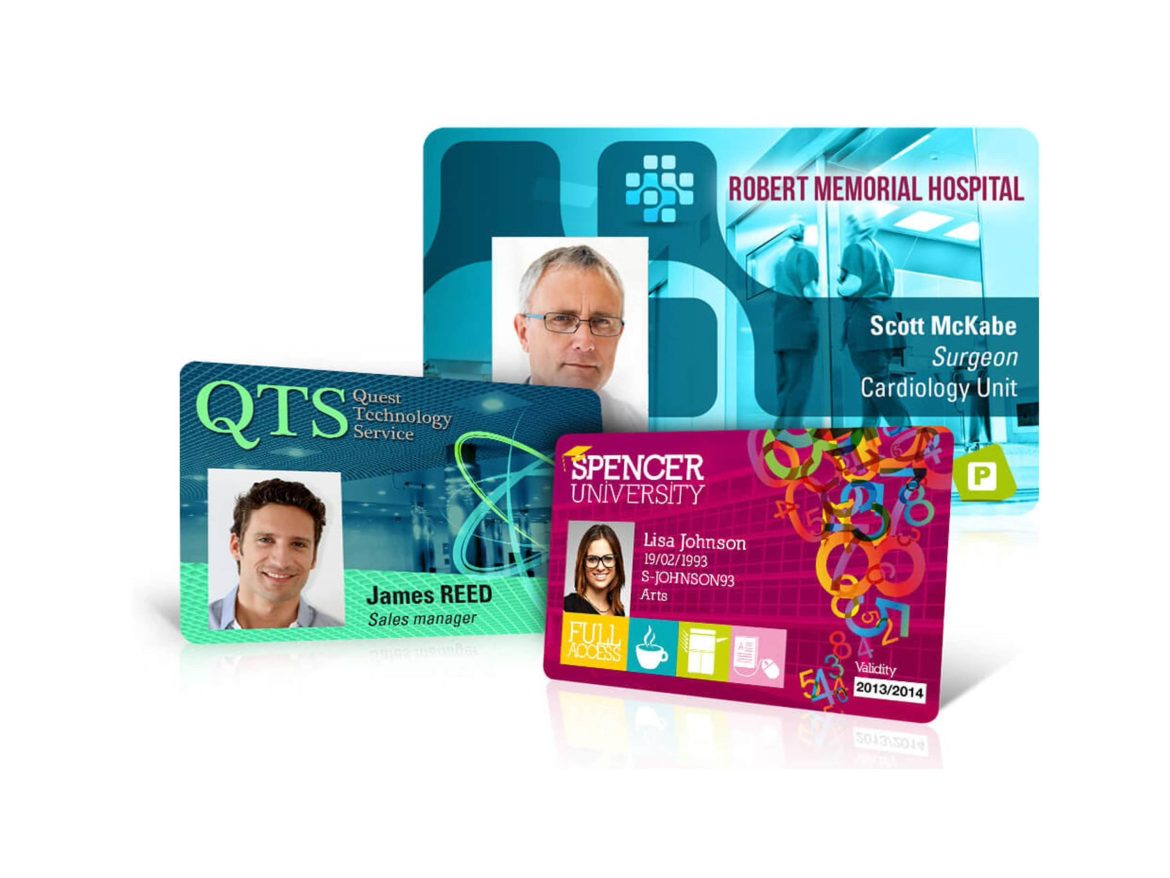

Whether it’s a plastic ID card that is designed to be an access control entry pass for your staff, or a card used by your loyalty program members, creating customized cards can give your organization a great branding opportunity. To help you get started, we’ve put together a guide to explain how PVC cards are made and what they can offer your business.

PVC ID cards are typically printed using a dye sublimation printer. A ribbon is rolled up with panels of the primary colors (Yellow, Cyan and Magenta) along its length and then inserted into the printer, where a print head that uses heated thermal elements to evaporate the ink onto the card. The result is a full color, durable PVC card that can be used for a variety of applications.

If your company needs a high volume of custom cards, you should invest in a digital LED UV printer that offers the ability to print full color with graphics on both sides. These printers are able to provide your organization with an affordable, high-quality card printing solution that is easy to operate and maintain.

Instant ID card issuance systems are also available that allow for the integration of features like inline magnetic stripe encoding and metal business cards wholesale smart chip encoding, as well as additional security enhancements like tactile impression printing. This can make your plastic ID cards more secure and convenient to use, while still allowing you to customize them to fit your brand.

Material

PVC is the standard ID card material that is used for most printing needs. It is durable, scuff and scratch resistant and available in a variety of colors and thicknesses to meet the needs of most applications.

However, not all cards are made with the same materials and the outer surface of a card can have a big impact on its durability, how well it prints and how long it will last. The two most important factors in the longevity of an ID card are its lamination and its thickness. The thicker the card, the more protection it will have and the longer it will last.

The other factor is the type of printing that will be done on the card. For example, dye sublimation printing will require a plastic that is able to withstand the high heat that is applied during this process. Composite cards are a good choice for this type of printing, as they have a higher tolerance to heat and will not warp or bend like a standard PVC card would.

Earth-friendly cards are also available, made with either BioPVC which is made from a natural plant material or recycled PVC that is produced by using less energy during manufacturing. These are a great choice for offices that want to be more environmentally conscious in their operations. Both options offer the same durability and quality of a standard ID card but have a much lower environmental impact.

Printing

PVC cards can be printed with a variety of images, logos and text to help your business create a professional image for itself. They can also be made to include bar codes, encoded magnetic stripes and smart card chips for security and fraud prevention purposes.

PVC ID card printing is usually done by dye sublimation or reverse transfer. Both processes produce high-quality, durable and long-lasting plastic ID cards. With dye sublimation, a ribbon is inserted into the printer and a thermal print head passes over it. The heat of the print head metal business cards wholesale causes the ribbon to melt and transfer the ink to the surface of the PVC card.

Reverse transfer printing is a popular option for PVC cards that need to be highly secure, like proximity and RFID cards. With this process, the card itself isn’t printed, but instead a clear mylar film overlay is printed with the card’s reverse image and then applied to the card. The film protects the card and makes it nearly impossible for unauthorized personnel to read the information on the card.

Most PVC ID card printers are designed to create standard credit-card sized badges that are 3.375″ x 2.125″ (CR80) in size and 30 mil thick. Some are also designed to create composite PVC-PET cards, which are made of 60/40 blends of PVC and PET plastic, or holograph overlays for added protection against counterfeiting.