PCBA Coating: Enhancing the Durability and Performance of Electronic Components

Introduction:

In today’s rapidly advancing technological era, electronic devices have become an integral part of our lives. From smartphones to smart appliances, these gadgets rely on complex circuit Aluminum PCB boards that contain a multitude of electronic components. To ensur PCBA Coating e their longevity and performance, a crucial step in the manufacturing process is applying a protective coating known as PCBA coating.

Manufacturing Process:

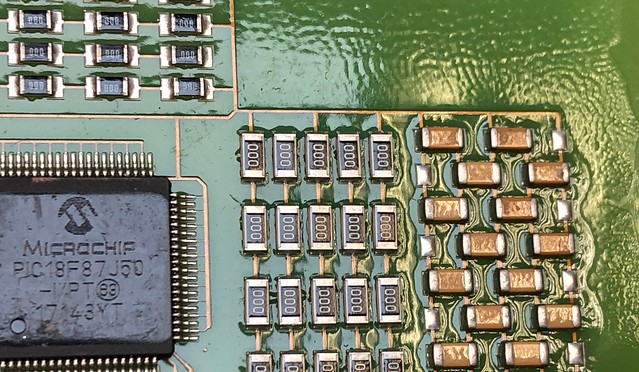

The process of PCBA coating involves the application of a thin, protective layer onto printed circuit boards (PCBs) or assembled PCBs. This can be done through vari

ous methods such as spray coating or dip coating. The purpose is to create a barrier between the sensitive electronic components and external factors such as moisture, dust particles, chemicals, and temperature variations.

Characteristics a PCB assembly coating nd Advantages:

1. Solder mask application: A key aspect of PCBA coating is ensuring proper solder mask application. It helps prevent solder bridges while maintaining good electrical insulation properties.

2. Surface protection for electronic components: The primary function of PCBA coatings is to protect delicate surface-mounted components from potential damage caused by environmental factors.

3. PCB assembly coating: By applying coatings during the assembly stage, it becomes easier to ensure complete coverage over intricate circuitry patterns.

4 .Board level conformal coating: Conformal c Ceramic PCB oatings provide excellent resistance against corrosion while offering greater support for high-frequency operating conditions.

Usage Methodology:

Implementing PCBA coatings requires precision and adherence to industry standards:

a) Pre-cleaning: Before applying an PCBA Coating y form of protective coat, it is essential to clean the board surface thoroughly using appropriate cleaning agents.

b) Selection of suitable materials: Depending on the specific

requirements (such as desired thickness or mechanical flexibility), choosing compatible materials for PCBA surfaces plays a crucial role in achieving optimal result

s.

c) Application technique: Whether opting for spraying or dipping methods depends upon several factors like batch size or criticality of the component.

Selecting the Right Product:

When choosing a PCBA coating, consider the following factors:

1. Compatibility: Ensure that the chosen coating material is compatible with both your PCB substrate and electronic components.

2. Environmental conditions: Evaluate whether the coating provides adequate protection against specific env PCBA Coating ironmental parameters such as humidity, temperature, or dust exposure.

3. Application method: Verify if the preferred application Surface protection for electronic components technique suits your manufacturing setup and requirements.

Conclusion:

PCBA coatings play an essential role in enhancing durability, reliability, and electrical performance for electronic components. By protecting PCBs from external elements like moisture, dust particles, and chemicals they help extend product lifespan. Proper selection of materia Solder mask application ls and application methods are crucial to achieving desired results. Therefore, it is recommended to consult with a reputable supplier who understands your unique needs while offering quality products like aluminum PCB or ceramic PCB equipped with smart door lock cap Smart door lock supplier abilities.

By incorporating PCBA coatings into electronic devices’ assembly process effectively allows manufacturers to deliver innovative products that can withstand varying environments while ensuring optimal performance levels—the key to success in today’s competitive market.