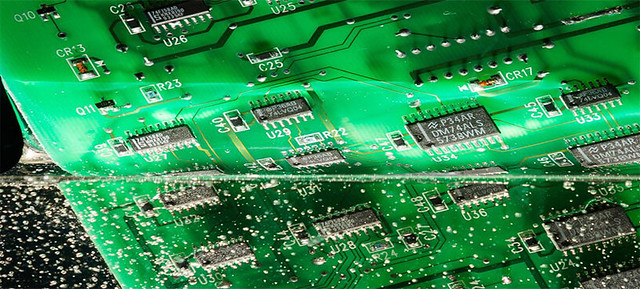

PCBA Coating: Protecting Circuit Board Assemblies

Introduction:

In the world of electronics manufacturing, it is essential to ensure that circuit board assemblies (CBAs) are properly protected. Component-level encapsulation plays a crucial role in Aluminum PCB safeguarding sensitive electronic components from environmental factors such as moisture, dust, and temperature variations. One effective method of protecting CBAs is through Ceramic PCB the use of PCBA coating. This article will explore the manufacturing process, features, advantages, usage methods, product selection criteria for PCBA coatings.

Manufacturing Process:

PCBA coating involves applying a protective layer to circuit boards using various methods such as spraying or dipping. Before the coating application, thorough cleaning and drying are done to remove any impurities or residues left during assembly processes. Once clean and dry, the selected coating material is applied evenly across the surface using specialized equipment or machinery.

Features of PCBA Coating:

1. Waterproof: The primary purpose of PCBA coatings is to protect against moisture ingress PCBA Coating which can cause short circuits and corrosion.

2. Dustproof: The protective layer acts as a barrier against particle

s that may hamper electrical connections on PCBs.

3. Chemical Resistance: PCBA coatings offer resistance against chemicals present in harsh industrial environments.

4. Thermal Management: Certain types of coatings provide additional thermal management capabilities by enhancing heat dissipation from components.

Advantages of Using PCBA Coating:

1.Protecting Electronic Components:The most significant advantage of using PCBA coating lies in its ability to protect delicate electronic components from potential damage caused by external factors such as humidity and contaminants like dust or debris.

2.Extended Lifespan:By add PCBA Coating ing an extra layer of protection with suitable tye,the overall lifespan

of CBAs can be significantly increased.this results in improved reliability while reducing maintenance costs associated with repairs or replacing damaged boards.

Usage Methods:

To achiev PCBA Coating e optimal protection for CBAs,

here are some recommended usage methods when applying PCBA coatings:

1. Select the Right Coating Material: Depending on the environmental condit

ions and specific requirements, choose a suitable coating material such as acrylic, silicone, epoxy or polyurethane.

2. Apply Uniform Coating Thickness: Ensure an even coating thickness across all areas of the circuit board to guarantee consistent protection for every component.

3. Drying and Curing Process: Follow manufacturer guidelines for proper drying/curing time so that the coating fully adheres to the PCB surface and attains optimal protective properties.

How to Choose PCBA Coating Products:

When selecting a PC Smart door lock supplier BA coating product,some crucial considerations include:

1.Resistance Properties:Check if the chosen coating offers resistance against moisture,dust,and chemicals typically found in your application environment.Having higher dielectric strength will increase its ability to withstand high voltage or electrical insulation requirements

Keep in mind,your specific industry needs might require different standards of corrosion protection,determine whether UL recognized/approved conformal coatings are necessary in your case.

3.Manufacturer Experience:Choose products from reliab Circuit board assembly protection le manufacturers with extensive experience in producing high-quality PCB coatings.Look for certifications like ISO9001 which en PCBA coating sure stringent quality control procedures are followed at each manufacturing stage,and technical support available when needed.

Conclusion:

PCBAs play a vital role in numerous electronic devices ranging from smartphones to industrial machinery.Component-level encapsulation through PCBA coatings is crucial

in protecting these assemblies from potential damage due

to contact with harsh environments or unwanted contaminants.By understanding features,advantages,application methods,and selection criteria associated with PCBA coatings,

manufacturers can make informed decisions regard Component-level encapsulation ing their production processes.Remember,the right choice of PCBA coatinե