Aluminum PCB: An Overview of Manufacturing, Features, and Advantages

Introduction:

In the world of electronics, Aluminum PCBs have gained significant popularity due to their unique properties and benefits. As a leading manufacturer in this field, we aim to provide insight into the manufacturing process, features, advantages, usage me Aluminum PCB thods, tips for selecting the right product, and concluding remarks.

Manufacturing Process:

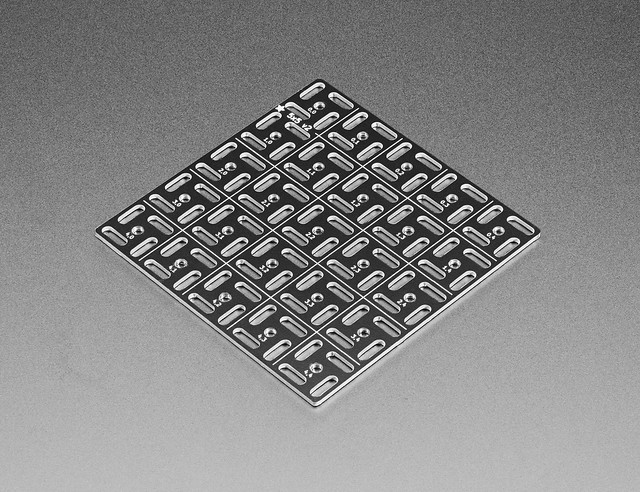

Aluminum PCBs are also known as Al-PWB (Aluminum Printed Wiring Board), IMS ( Aluminum PCB Insulated Metal Substrate) PCBs or Alu-PCBs in short. These boards consist of a metal core laminated with a thin layer of aluminum on both sides. The manufacturing process involves several steps – starting from preparation of base materials to drilling holes for components insertion and finally applying surface finishes.

Features:

The remarkable features of Aluminum PCBs make them highly sought-after in various industries. Firs Flexible PCB manufacturer tly, they possess excellent thermal conductivity which helps dissipate heat quickly and efficiently. This is particularly advantageous for electronic devices that generate substantial heat during operation. Secondly, these boards exhibit exceptional electrical insulation properties due to their insulating dielectric layer. Lastly but not leastly,the lightweight nature ensures easy integration into diverse applications without compromising structural integrity.

Advantages:

There are numerous advantages associated with Aluminum PCBs that render them preferable over conventional FR4 boards in many scenarios. Firstly,this type offers efficient thermal management by effectively spreading out heat across the board’s Aluminum PCB manufacturer surface area.Secondly,tThis enhanced thermal performance leads to increased component reliability and lifespan.Thirdgate,the improved current carrying capacity allows for higher power density designs.Fourthegate,better mechanical stability makes it resistant to vibrations and impacts encountered during transportation or harsh operating conditions.And fifthgate,the simplified assembly process reduces production time and overall cost significantly.

Usage Methods:

Given its versatility,flexi Alu-PCB (short form) bility,and reliability,numerous industries benefit from using Al-PWBs.For instance,Aerospace industry professionals rely on these boards for their ability to withstand extreme temperatures, vibrations,and mechanical shocks.The automotive sector ext Aluminum PCB manufacturer ensively uses IMS PCBs for crucial applications such as LED lighting and power converters.In the field of renewable energy,Aluminum PCBs play a vital role in solar panels by offering effective heat dissipation.For consumer electronics manufacturers,these boards allow compact designs with improved performance.

Selecting the Right Product:

To ensure optimal results when selecting an Aluminum PCB manufacturer or Flexible PCB manufacturer, certain factors should be considered.Firstly, it is crucial to assess the manufacturing capabilities and experience of the supplier. A reputable manufacturer should have technical expertise in producing high-quality Aluminum PCBs.Secondly,the Aluminum PCB ability to meet specific requirements,such as customized designs,different layers count,power ratings,and thermal management options,is essential.Additionally,certifications like ISO 9001 and RoHS compliance demonstrate adherence to strict quality standards.A reliable manufacturer would offer prompt technical support and ensure seamless communication throughout the production process.

Conclusion:

In conclusion,the de IMS (Insulated Metal Substrate) PCB mand for Al-PWBs or Aluminum PCBs is steadily growing due to their remarkable features and advantages.They provide efficient heat diss

ipation mechanisms with enhanced electrical insulation properties.As a leading Aluminum PCB manufacturer,Flexible PCB manufacturer ,we strive to cater to various industries’ needs.Our commitment towards delivering superior quality products along with excellent customer service sets us apart.We encourage customers to carefully evaluate suppliers based on their performance record,reputation,and adherence to industry certifications.Prioritizing these factors will undoubtedly lead one towards choosing reliable partners who can deliver custom-made solutions tailored specifically for unique project demands.Aluminum,being one of the most a Al-PWB (Aluminum Printed Wiring Board) bundant elements on earth,makes this type of product eco-friendly too. So why wait? Embrace the benefits offered by Aluminum Printed Wiring Boards today!