The Benefits and Manufacturing of Aluminum PCB

Aluminum PCB is an essential component in the electr Flexible PCB manufacturer onic industry, providing a reliable solution for various applications. As a type of metal core PCB, it offers unique characteristics that make it suitable for demanding environments and high-power applications. In this article, we will explore the manufacturing process, features, advantage Aluminum clad PCB s, usage methods, tips for selecting the right product manufacturer, and conclude with its significance in modern electronics.

Manufacturing Process:

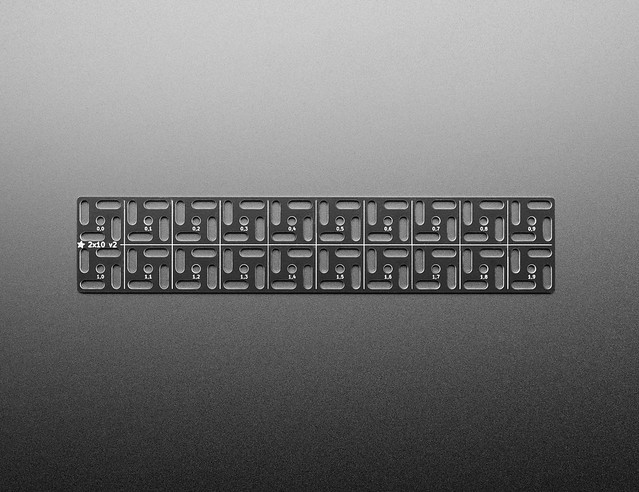

Aluminum PCBs are manufactured using a specialized process that involves combining layers of aluminum substrate with copper traces. The first step involves drilling holes on the base material to create uniform openings for components placement. Then a layer of dielectric material is added to insulate the conductive paths from each other. Finally, a thin layer of aluminum or copper is dep Al-PWB (Aluminum Printed Wiring Board) osited on both sides to protect against corrosion and provide better heat dissipation capabilities.

Features:

One distinguishing feature of Al Aluminum PCB manufacturer uminum PCBs is their excellent thermal conductivity properties. Thanks to aluminum’s high thermal conductivity value compared to other metals used in circuit boards like fiberglass or ceramic substrates. This property enables quick heat dispersal from power devices and extends their lifespan by preventing overheating issues.

Advantages:

1. Heat Dissipation: Due to its unique structure and materials used during manufacturing, Aluminum PCBs offer excep Aluminum PCB tional heat dissipation capabilities.

2. Durability: The use of aluminum as the base material ensures higher mechanical strength com Aluminum PCB pared to traditional FR4 boards.

3. Lightweight: Aluminum’s lightweight nature makes it ideal for portable devices where weight reduction is crucial.

4.Flexibility: Certain manufacturers produce flexible Aluminum PCBs customized into different shapes based on customer requirements.

5.Cost-effective: Despite its superior performance characteristics compared to standard circuit boards though costly than conventional ones; however it can save money o Aluminum PCB manufacturer ver time owing directly towards enhanced device longevity.

Usage Methods:

Aluminum clad PCB finds extensive application in various industries such as automot Metal core PCB ive lighting systems,power converters, audio amplifiers, LED technology, and high-power equipment.

Choosing the Right Manufacturer:

To ensure optimal results and reliability in your electronic projects, selecting the right aluminum PCB manufacturer is crucial. Consider these factors before making a decision:

1. Quality: Look for manufacturers with certifications like ISO 9001 to guarantee their quality control standards.

2. Experience: Pre Aluminum PCB fer companies with years of experience and expertise in manufacturing Aluminum PCBs.

3. Customization: Check if the manufacturer offers flexible design options tailored to your requirements.

4.Reviews: Read customer revi

ews or ask for references from trusted sources about their experience with that particular manufacturer.

In conclusion, Aluminum PCBs provide an efficient solution for applications requiring heat dissipation and durability. Its thermal conductivity p

roperties make it a go-to choice in various industries where temperature management is critical. By choosing a reliable manufacturer and considering important factors like quality, customization options, and user reviews; one can ensure successful integration of this valuable component into their electronic designs.