PCBA Coating: Enhancing the Durability of Printed Circuit Board Assemblies

Introduction:

In the world of electronics manufacturing, ensuring the l

ongevity and reliability of printed circuit board assemblies (PCBAs) is crucial. One effective way to achieve this is through PCBA coating. This article will delve into the manufacturing process, characteristics, advantages, application methods, how to choose the right product, and ultimately provide a conclusion on why PCBA coatings are essential in surface protection for electronic components.

Manufacturing Process:

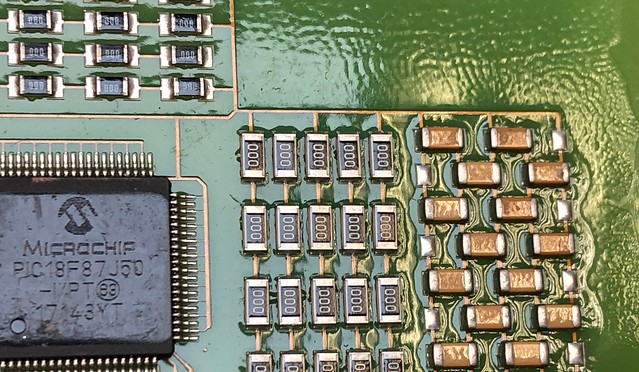

PCBA coating involves applying a protective layer onto assembled PCBs. This can be done using various technique PCB Assembly s such as spraying or dipping the boards into a liquid coating material. The most commonly used materials inclu PCBA Coating de epoxy resin coatings and silicone-based compounds. These products offer excellent adhesion properties and ensure complete coverage over sensitive components.

Characteristics:

The primary purpose of PCBA coatings is to safeguard electronic components against environmental factors like moisture, dust particles, chemicals, and temperature fluctuations. A high-quality coating acts as a barrier that prevents potential damage caused by these external elements. Additionally, these coatings offer electrical insulation properties that further enhance their effectiveness in maintaining optimum performance levels.

Advantages:

1. E PCBA coating nhanced Reliability: By providing an extra layer of protection to PCBAs, coating significantly increases their durability while reducing failu PCBA Coating re rates due to environmental stressors.

2. Increased Lifespan: PCBAs subjected to corrosive environments may experience degradation over time; however,

with proper coating applications,

their lifespan can be prolonged.

3.Risk Mitigation:

PCBA

coated surfaces

decrease risks

of

shor PCBA Coating t-circuits

and

leakage currents;

thus,making it safer for

end-users.

Usage Methods:

There are two popular methods for applying PCBA coatings: selective coating and full-coverage coating.

1.Selective Coating: Often preferred when only specific areas require protection.This method entails masking off

areas that don’t require coating and applying the protective layer to designated regions.

2.Full-Coverage Coating: This technique involves covering the entire PCB, including all its componen PCB Assembly ts, with a uniform layer of protective coating. It is preferred when complete protection against potential threats is required.

How to Choose the Right Product:

Considerations for selecting the appropriate PCBA coating include:

1. Environmental Conditions: Evaluate the PCBAs’ intended application environment, assessing factors such as humidity,

temp

erature range, chemical exposure, and any other unique challenges it may encounter.

2.Coating Material Compatibility: Ensure compatibility between the chosen coating material and your PCBA’s

construction materials (e.g., copper traces or solder joints).

3.Application Method Suitability: Check if your manufacturing process aligns with how a particular coating needs to be applied.

Conclusion:

PCBA coatings are indispensable for maintaining electr

onic component reliability in various industries. Their resilience against environmental stressors provides peace of mind while their electrical insulation properties offer added advantages. By implementing suitable PCBA coatings such as So Solder mask application lder mask application or Printed circuit board assembly coatings during manufacturing, you can significantly enhance your products’ durability and lifespan.

In summary,the selection,integration,and careful consideration of PCBA coatings within PCB AssemblyorElectronic Manufa PCBA Coating cturing Services(EMS) processes will contribute towards creating high-quality products capableofwithstanding adverse operating conditions.And thus,a prolonged overall shelf-life ofApparatusesand Systemsystems+andSystems.The market offers a wide rangeofsolutionsofonditionings suitablesforSMT、Through-Hole(passiveparts)、BGA,CSP,

Co- PLANARmodulesinterconnectsandin/ormixedproductions used byODM/OEMcompanies。

By prioritizing safety,reliability,sustainableperformanc Printed circuit board assembly coating e,

lowfailure rates,and anextendedlifespan,the use ofPCBASAssembly Ccoatings has becomean industry-standardpracticewith influentialeffects forbothmanufacturersandconsumersalike.