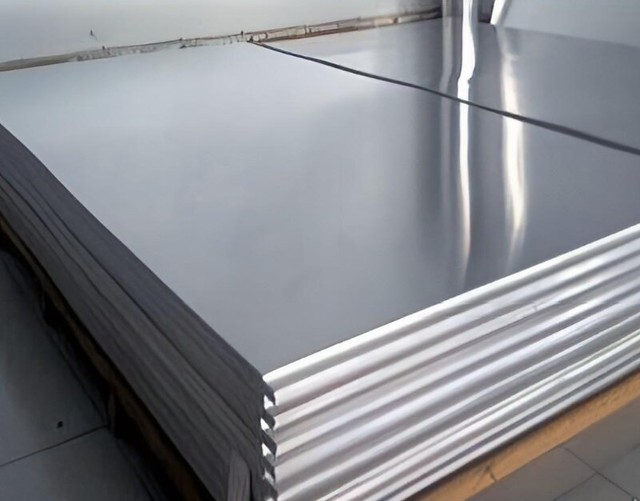

Alloy Sheet: A Powerful Material for Various Industries

Introduction:

In today’s modern world, industries are constantly in search of materials that offer durability, strength, and versatility. One such material that has gained significant popularity is the al

loy sheet. This article aims to explore the manufacturing process, characteristics, advantages, usage methods, tips for selecting this product, and ultimately draw a conclusion about its effectiveness.

Manufacturing Process:

The production of an alloy sheet involves combin Alloy Sheet ing different metals or elements to create a new material with enhanced properties. Titanium alloy sheets are produced by subjecting titanium and other metallic elements to intense heat treatment followed by rolling processes. Tinplate sheets are manufactured by coating thin steel sheets with a layer of tin through electrolysis or hot dipping methods.

Characteri Metal plate stics:

1. High Strength Carbon Steel Plate: Alloy sheets often exhibit excellent tensile strength and resistance to impact due to the presence of carbon steel plates in their composition.

2. Alloy Sheets (x4): The repeated mention underscores their significance within this context.

– Provide

s exceptional corrosion resistance while maintaining structural integrity.

– Exhibits superb ductility and malleability lending itself well to various fabrication processes.

– Offers good thermal conductivity allowing efficient heat dissipation in applications requiring tem Alloy Sheet perature regulation.

– Shows high elec Alloy Sheet trical conductivity making it suitable for electrical contact components.

Advantages:

– Versatility: Alloy sheets find extensive use across numerous industries including automotive manufacturing, aerospace engineering,

construction sector among others due to their diverse range of physical p Alloy Sheet roperties.

– Durability: Thanks to their inherent toughness and resilience against harsh environments & demanding working conditions; they have a prolonged service life when compared with conventional metal plates.

Usage Methods:

1. Automotive Industry: Alloy sheets play a crucial role in constructing vehicle bodies owing to their lightweight nature combined with superior strength and rigidity resulting in fuel efficiency improvements without compromising safety standards,

2. Electrical Applianc Titanium alloy sheet es Manufacturing: The excellent electrical conductivity makes these alloys ideal for manufacturing electrical contacts, connectors, and terminals.

3. Construction Sector: Alloy sheets find applications in roofing materials, cladding systems as well as structural comp High Strength Carbon Steel Plate onents due to their corrosion resistance and ability to withstand adverse weather conditions.

How to Choose the Right Product:

– High Strength Carbon Steel Plate Consider specific requirements such as mechanical properties (tensile strength, yield stress), thickness, width, surface finish etc., depending on the intended application.

– Evaluate cost-effectiveness by comparing prices from different suppliers while ensuring quality standards are met.

Conclusion:

Alloy sheets have emerged as Tinplate a highly sought-after material due to their exceptional strength-to-weight ratio combined with excellent physical properties. Whether it be titanium alloy sheets or tinplate alloys – both offer numerous advantages and diverse application opportunities across various industries. By understanding their manufacturing process, characteristics, advantages & usage methods while following proper selection guidelines; businesses can harness the incredible potential of al

loy sheets in their respective sectors resulting in enhanced performance and overall competitiveness.