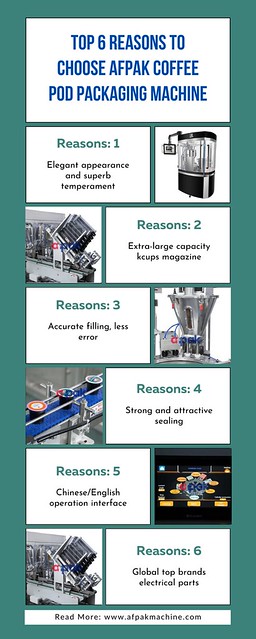

Filling Machines Supplier: A Comprehensive Guide to Filling Machinery

Introduction:

In the manufacturing industry, filling machines play a crucial role in ensuring the efficient and accurate packaging of various products. As a Filling Machin Filling Machine Supplier e Supplier, it is important to understand the different aspects of filling machinery that make them an essential part of any production line. This article will discuss the manufacturing process, features, advantages, usage methods, tips for selecting these products, and provide a concluding note on their significance.

Manufacturing Process:

As a reputable Manufacturer of fillers and Source of filling systems, developing high-quality filling machines inv Manufacturer of fillers olves several intricate steps. It starts with designing robust frameworks using advanced technology such as Computer-Aided Design (CAD). The sel filling machinery ection and integration of key components like pumps, valves, sensors are carefully considered to ensure optimal performance. Additionally, stringent quality checks guarantee that each machine adheres to industry standards.

Features:

The range of features offered by modern filling machines showcases their versatility in meeting diverse requirements:

1. Automated Operation: Filling machines streamline production processes through their automated functionalities. They can accurately measur

e quantities and use timing mechanisms for consistent results.

2. Customized Filling Options: Manufacturers can customize these machines to accommodate various types and sizes of containers or packages.

3. Leakage Prevention Mechanisms: Advanced models include leak detection s Filling Machine Supplier ensors that prevent product spillage during operation.

4. Easy Maintenance: The design emphasizes easy disassembly and cleaning procedures which minimize downtime.

Advantages:

By investing in high-quality filling machinery from a trusted Filling machine distributor like ours,

companies gain numerous advantages:

1.Cost Savings: These machines help optimize production efficiency by reducing manual labor requirements.

2.Accuracy & Consistency: Pre filling machinery cise measurements result in uniform product distribution leading to improved customer satisfaction.

3.Reduced Product Waste: Efficient control mechanisms minimize product wastage due to overflow or leakage.

4.Increased Safety Standards:auser<|im_sep|>Stringent safety measures integrated into the machines ensure a secure working environment for employees.

Usage Methods: Filling machine distributor

To maximize the benefits of filling machinery, organizations should consider the following usage methods:

1. Proper Configuration: Customize machine settings based on the product’s viscosity and packaging requirements.

2. Regular Maintenance: Adhere to manufacturer recommendations regarding scheduled inspections, lubrication proc Filling Machine Supplier edures,

and replacement intervals to maintain optimal performance.

3. Employee Training: Comprehensive training programs will enable workers to Filling Machine Supplier operate these machines effectively while adhering

to safety regulations.

How to Select Filling Machines Supplier:

Choosing the right Filling Machine Supplier requires careful consideration. Here are some key factors one should evaluate:

1.Product Range & Specializations: Ensure that the supplier offers a wide range of machines suitable for your industry-specific needs.

2.Quality Assurance Measures: Inve

stigate if the supplier has robust quality control measures in place during manufacturing

and testing processes.

3.After-Sales Support:auser<|im_sep|>Consider suppliers who provide prompt technical support, spare part availability, and assistance with installation,

maintenance, and repairs.

4.Customer Reviews & Reputation: Read customer testimonials/reviews or seek referrals from industry peers regarding their experience

with various suppliers.

Conclusion:

Filling machinery con Source of filling systems tinues to revolutionize manufacturing industries globally by providing accurate measurements,

efficiency improvements,and cost-saving solutions.Professional Manufacturer of fillers like us offers customi

zed

solutions tailored according to specific business requirements.Choosing an experienced Filling Machine Supplier ensures high-quality products

that enhance overall productivity.Stay ahead in your production line by incorporating advanced filling technology!