Lithium-Ion Battery Pack

Lithium-ion batteries are used in a variety of applications. From portable electronics like phones, laptops and tablets to electric vehicles and renewable energy storage systems.

They have high energy density and a long lifespan. This technology has led to an impressive advancement in portable electronic devices. It also helped bring about large-scale energy storage solutions.

Safety

Lithium-ion batteries power a wide range of hardware, from smartphones and laptops to electric vehicles and even residential solar battery systems. But these batteries can be dangerous if not handled correctly. This is because lithium-ion batteries contain power cells, which can produce an internal short circuit and burn or explode if damaged.

This type of mechanical abuse often occurs in the form of physical collisions, which causes stress to be induced at the weakest point of the battery pack, namely the cell. This stresses the individual cathodes and anodes, which then generates side reactions that can lead to thermal runaway (burning).

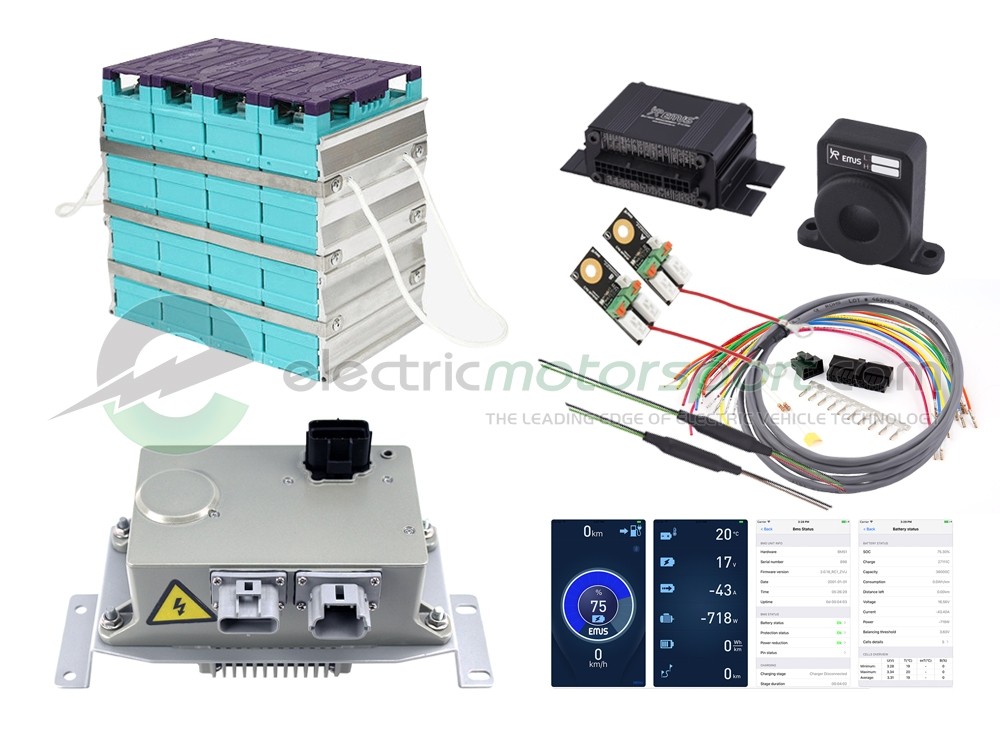

To reduce this risk, a battery management system (BMS) monitors the status of each individual cell within a battery pack to prevent overcharging or excessive temperature increase, which could result in a fire. A BMS can also be connected to cooling provisions, which may reduce the temperature of the battery pack if it is getting too hot. NREL’s Battery Internal Short-Circuit Device and Isothermal Battery Calorimeter can evaluate these and other battery safety issues in cells, modules, sub-packs, full-size battery packs and energy systems.

Durability

The batteries used to power our mobile devices and electric cars are built with lithium-ion technology. These batteries are characterized by their high energy density and long lifespan. They also have fast charge and temperature operating windows, which allows them to be fine-tuned for specific performance needs.

These batteries are safer and lighter than other battery chemistries, such as nickel-metal-hydride (NiMH). They are also able to sustain high internal pressures, which is important in aerospace applications, such as Boeing 787 fleets. However, the batteries are still subject to thermal runaway, which can lead to fire and explosions.

The batteries are available in cylindrical, prismatic, coin and pouch cells. The cells are arranged in an array and connected to create the battery pack. A battery pack’s capacity is determined by its number of cells. To ensure safety, the battery cells must be properly balanced. If the battery cells are not Li-ion battery pack matched to each other, minor voltage differences can accumulate and compromise cell performance. In addition, the battery must be stored in an environment that is safe to operate.

High Energy Density

Lithium-ion batteries have high energy density, meaning they can store a lot of power in a small package. They’re used in laptops, phones, cars and other consumer devices. They can be recharged over and over again without losing much of their stored energy.

To achieve high energy density, manufacturers have to change several battery components. They can use different cathode and anode materials, increase electrode loading mass, reduce the ratio of electrolyte volume to battery capacity (E/C), and adopt lighter collectors, separators, packaging and other materials.

Another way to improve energy density is by using solid electrolytes, which are non-flammable in the case of a short. A solid electrolyte also reduces self-discharge, which allows the battery to retain its charge for longer.

Long Lifespan

Like other rechargeable batteries, lithium-ion cells lose some capacity with regular use and recharging. However, recharging the battery before it’s nearly depleted slows this degradation, prolonging battery life. In fact, most lithium-ion batteries are warranted for 500 charging cycles – far more than the lifespan of nickel-cadmium or nickel-metal-hydride technology.

While some companies imply that lithium-ion batteries have memory and require scheduled cycling, this is untrue. Modern Li-ion batteries perform best when they experience balanced cycles of charge and discharge. This is why it’s recommended to store them at 50% capacity when they’re not in use.

In addition to storing the batteries at a lower charge level, the lithium-ion pack’s internal chemistry works to maintain the peak voltage of each cell. This is a leading indicator of battery health, and it reduces power loss from internal resistance and self-discharge. Plus, many manufacturers employ overload and overcharge protections that help to prolong a lithium-ion battery’s lifespan. These are technologies that weren’t commonly available on NiCad and NiMH batteries. These features allow the batteries to reach their expected lifespan without suffering from any premature failures or degradation.

Rechargeable

Lithium-ion battery technology provides high energy density in a compact package. It is also highly scalable and offers a wide operating temperature range. It is also easy to customize to meet specific customer needs by selecting the right positive and negative electrode materials, chemistries and designs for the cell.

The positive and negative electrodes are separated by a thin sheet of micro-perforated plastic (separator). During Li-ion battery pack charging, lithium ions move from the positive to the negative electrode through the electrolyte. When the battery is discharged, the ions migrate back from the negative to the positive electrode through the separator and the electrolyte.

A large battery pack contains many individual cells that are connected in series to provide the required voltage for a particular application. A computer that manages the batteries controls their operation to ensure safe and optimal performance. The battery packs are also equipped with protection circuits, shutdown separators and temperature sensors that help prevent overheating.